Waterproofing is a vital process in building and construction, designed to protect structures from water infiltration and moisture-related damage. It involves applying specialised materials to surfaces such as walls, roofs, and foundations to prevent leaks and preserve the integrity of the building. Waterproofing helps maintain a dry and safe environment, reducing the risk of mould growth, dampness, and structural weakening. With a variety of techniques and materials available, proper water sealing ensures long-term protection and helps prevent costly repairs, especially in areas exposed to high moisture, such as basements and bathrooms.

What Is Waterproofing in Building?

Waterproofing in building is the process of protecting structures from water damage. It stops water from entering walls, roofs, floors and other parts of buildings. Water can cause serious problems like cracks, mould and weak structures. Water barrier application creates a protective barrier that keeps buildings dry and safe. It helps buildings last much longer without costly repairs.

A study from Emerald Insight, entitled “Waterproofing integrity and water tightness of buildings in the tropic”, showed that recurrent leakage problems occur when design, installation, and maintenance are not adapted to local climate and use patterns.

Waterproofing in building uses different materials and methods depending on the area. Common waterproofing areas include:

- Roofs to stop rain from leaking inside

- Walls to prevent dampness and moisture

- Basements to keep groundwater out

- Bathrooms and kitchens to protect against splashes

- Balconies and terraces exposed to weather

Waterproofing in building is essential for every home and structure. Without proper Waterproof treatment, water slowly damages concrete, wood and metal. Damp buildings become unhealthy places with mould and bad smells.

What Is Waterproofing in Construction?

Waterproofing in construction is applying protective layers during the building process to stop water from entering. Workers add waterproofing materials as they build walls, floors and roofs. This creates a strong barrier against rain, groundwater and moisture. Construction waterproofing is planned before building starts. It becomes part of the structure itself. Good waterproofing in construction protects buildings for many decades. It costs less to waterproof during construction than to fix leaks later.

How does it work:

- Waterproofing in construction stops water from passing through

- Workers apply special coatings, membranes, or admixtures

- These materials fill tiny holes in concrete

- They create a sealed and protected surface

- Multiple layers give better protection than one layer

- Basements use thick waterproof membranes

- Walls usually use waterproof coatings

- This keeps the whole building dry and safe

What Is Waterproofing Foundation?

Waterproofing in foundation is protecting the bottom part of buildings from groundwater and soil moisture. The foundation sits underground where water pressure is very strong. Wet soil pushes water against foundation walls constantly. Without waterproofing, water seeps through concrete and damages the whole building. Foundation waterproofing stops this water before it enters. It creates a sealed barrier around the foundation. This keeps basements and ground floors completely dry and safe from water damage.

How does it work:

Waterproofing in foundation works by applying protective layers to the outside or inside of foundation walls. Workers can use:

- Thick waterproof membranes stuck to foundation walls

- Special coatings brushed onto concrete surfaces

- Drainage systems that carry water away from foundations

- Waterproof admixtures mixed into the concrete itself

What Is Waterproofing a Basement?

Waterproofing in basement is protecting underground rooms from water and dampness. Basements sit below ground level where water collects naturally. Groundwater pushes hard against basement walls and floors. Rain that soaks into soil adds more water pressure. Without waterproofing, basements become wet, mouldy and unusable. Basement waterproofing creates a dry space you can use safely. It stops water from seeping through walls, floors and ceiling areas completely.

How does it work:

Waterproofing in basement works by sealing all surfaces where water might enter. The process includes:

- Applying waterproof coatings to walls and floors

- Installing drainage systems to collect and remove water

- Sealing cracks and joints with special materials

- Adding sump pumps to pump water away

What Is Waterproofing Membrane?

Waterproofing in membrane is using thin sheets or liquid layers that form a waterproof barrier. Membranes are flexible materials that stick to surfaces and block water completely. They come as ready-made sheets or liquids that harden after application. Sheet membranes are unrolled and stuck down with special glue. Liquid membranes are painted or sprayed on surfaces. Both types create seamless waterproof layers. Membranes are very popular because they work extremely well against water pressure.

How does it work:

Waterproofing in membrane works by creating a continuous barrier with no gaps or holes. The membrane materials include:

- Bitumen sheets that stick to surfaces with heat or glue

- Rubber membranes that stretch and seal tightly

- Liquid polyurethane that forms flexible coatings

- PVC sheets that join together at edges

What Is Waterproofing Paint?

Waterproofing in paint is using special paint that stops water from soaking through walls and surfaces. This paint contains waterproofing chemicals mixed with regular paint ingredients. It looks like normal paint but creates a water-resistant barrier when it dries. Waterproofing paint is easy to apply with brushes or rollers. It works well on walls, concrete and masonry surfaces. People use it in bathrooms, kitchens and exterior walls. Waterproofing paint provides basic protection against moisture and light water exposure.

How does it work:

Waterproofing in paint works by forming a protective film over the surface when it dries. The paint contains:

- Special polymers that repel water

- Chemicals that seal tiny holes in walls

- Flexible ingredients that move with the surface

- Additives that prevent mould growth

How Does Waterproofing Work?

Waterproofing works by creating a protective barrier that stops water from passing through surfaces. Special materials are applied to walls, roofs and floors to seal them completely. These materials fill tiny holes and cracks in concrete and other building materials. The waterproofing layer bonds strongly to the surface underneath. Water cannot soak through this sealed barrier. Different waterproofing methods use different materials, but they all work the same way. They create a shield that keeps buildings dry and protected from moisture damage.

The waterproofing process includes:

- Cleaning the surface thoroughly to remove dirt and dust

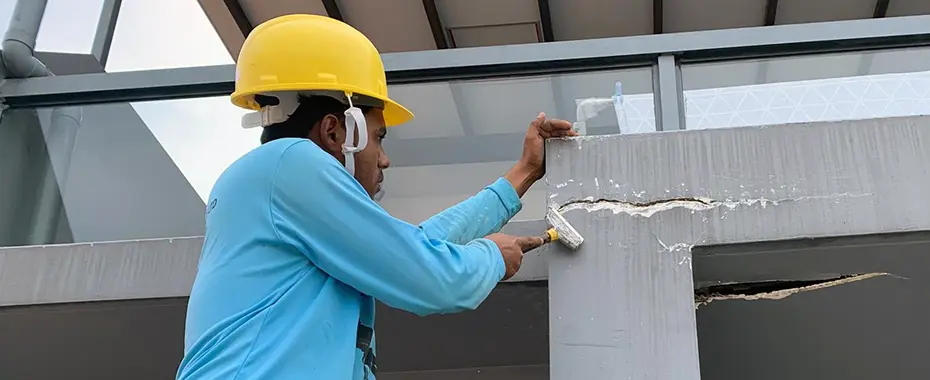

- Repairing any cracks or holes in the structure

- Applying waterproofing materials in layers

- Allowing each layer to dry completely

- Testing the waterproofing to ensure it works properly

What Are the Different Types of Waterproofing in a House?

The different types of waterproofing in a house are cementitious waterproofing, liquid membranes, polyurethane coatings, bituminous membranes, sheet membranes, crystalline waterproofing, PU injection, waterproofing plaster, and waterproof paints. Choosing the right type depends on where you need protection and how much water pressure the area faces.

1. Cementitious Waterproofing

Cementitious waterproofing is a cement-based coating that makes surfaces waterproof. It contains cement, sand and special chemicals mixed with water. This mixture is applied like plaster to walls and floors. It is one of the easiest water resistance treatment methods to use. Cementitious waterproofing is very popular because it is affordable and effective. It works well in areas that stay damp or wet all the time. The coating is rigid when it dries, so it is not suitable for areas that move or bend.

When to use:

- Bathrooms and shower areas

- Water tanks and swimming pools

- Basements and underground structures

- Wet balconies and terraces

- Foundations below ground level

How to use:

You clean the surface completely before applying cementitious waterproofing. Remove all dust, dirt and loose material from walls or floors. Fill any cracks with cement filler first. Mix the waterproofing powder with clean water according to instructions. Stir it well until no lumps remain. Apply the mixture with a brush or trowel in thin layers. Put on at least two coats for good protection. Let each coat dry before adding the next one. Keep the surface damp for a few days after application. This helps the waterproofing cure properly and become very strong.

2. Liquid Waterproofing Membranes

Liquid waterproofing membranes are liquid coatings that form a flexible waterproof layer when they dry. These liquids are usually made from polyurethane, acrylic or rubber materials. You apply them with a brush, roller or spray gun. The liquid spreads easily over surfaces and fills all gaps and corners. When it dries, it creates a seamless waterproof skin with no joints. Liquid membranes are very flexible and can stretch without breaking. This makes them perfect for areas that might move slightly over time.

When to use:

- Flat roofs and roof terraces

- Balconies and external walkways

- Bathrooms and wet areas

- Areas with complex shapes and many corners

- Surfaces that experience movement or vibration

How to use:

Clean the surface thoroughly and make sure it is completely dry. Repair any cracks or damage before starting. Apply a primer coat if the product instructions require it. Stir the liquid membrane well before use. Pour or brush the liquid evenly across the surface. Make sure you cover every part with no gaps. Apply the membrane in two or three thin coats rather than one thick coat. Each coat must dry completely before you add the next one. Pay extra attention to corners, edges and joints. Add reinforcement fabric between coats in areas with cracks. The final layer creates a smooth, waterproof finish.

3. PU (Polyurethane) Waterproofing

PU (Polyurethane) waterproofing is a highly flexible and durable waterproofing method using polyurethane-based materials. Polyurethane is a strong elastic material that stretches and moves with surfaces. It resists chemicals, weather and wear very well. PU waterproofing comes as a liquid that you apply to surfaces. It dries to form a rubber-like waterproof coating. This coating can expand and contract without cracking. PU waterproofing lasts for many years even in harsh conditions. It is more expensive than other methods but provides excellent protection.

When to use:

- Roofs exposed to sun and rain

- Parking areas and driveways

- Industrial floors with heavy use

- Balconies and terraces

- Areas requiring long-lasting protection

How to use:

Prepare the surface by cleaning it completely and repairing all cracks. The surface must be dry before you start applying PU waterproofing. Mix the polyurethane components according to the manufacturer’s instructions. Some PU products have two parts that you mix together. Apply the first coat with a brush, roller or squeegee. Spread it evenly across the whole surface. Let it dry for the time specified on the product label. Apply a second coat in the opposite direction to the first coat. This ensures complete coverage with no thin spots. You can add more coats for extra protection in high-risk areas. Keep the area dry during application and curing time.

4. Bituminous Waterproofing

Bituminous waterproofing uses bitumen, a thick black tar-like material, to create waterproof barriers. Bitumen comes from petroleum and is completely waterproof. It has been used for waterproofing for over a hundred years. Bituminous waterproofing comes in two main forms: liquid bitumen that you paint on, and bitumen sheets that you stick down. Both create strong, long-lasting waterproof layers. Bitumen works especially well below ground where it faces constant water pressure. It resists damage from soil chemicals and groundwater very effectively.

When to use:

- Building foundations and basements

- Underground car parks

- Flat roofs on commercial buildings

- Bridge decks and tunnels

- Areas with high water pressure

How to use:

Clean the surface thoroughly and make sure it is completely dry. Apply a bitumen primer coat first to help the waterproofing stick better. For liquid bitumen, heat it until it becomes runny enough to brush or pour. Apply it in thick coats using a brush or mop. Build up several layers for strong protection. For bitumen sheets, unroll them onto the primed surface. Heat the sheet with a torch to make it stick down. Overlap sheets at joints by at least 10 centimetres. Press down firmly to remove air bubbles. Seal all edges and corners carefully. The bitumen hardens as it cools, forming a tough waterproof barrier.

5. Sheet Membrane Waterproofing

Sheet membrane waterproofing uses pre-made waterproof sheets that are stuck or laid onto surfaces. These sheets are manufactured in factories to exact standards. They come in rolls of different widths and thicknesses. Common sheet materials include bitumen, PVC, rubber and polyethylene. Sheet membranes provide very reliable moisture protection system because they have consistent quality. They are quick to install compared to liquid methods. The sheets create a complete barrier with overlapping joints. Sheet waterproofing is very popular for large flat areas like roofs.

When to use:

- Large flat roofs on houses and buildings

- Terrace gardens and green roofs

- Basement floors and walls

- Foundation waterproofing

- Water features and pond linings

How to use:

Prepare the surface by making it smooth, clean and dry. Remove any sharp objects that might puncture the sheet. Apply a base coat or adhesive according to the sheet type. Unroll the waterproof sheet carefully across the surface. Make sure sheets overlap by the amount specified in the instructions. Stick down the sheet using adhesive, heat welding or mechanical fixing. Press firmly to remove air pockets underneath. Seal all overlaps and joints properly to prevent leaks. Cut sheets neatly around pipes and edges. Add an extra protective layer on top if needed. Check the entire surface for any gaps or damage before finishing.

6. Crystalline Waterproofing

Crystalline waterproofing is a special chemical treatment applied to concrete that makes it waterproof from inside. The chemicals react with water and cement in the concrete to grow tiny crystals. These crystals fill up all the tiny holes and cracks in the concrete. The crystals block water but still let the concrete breathe. This waterproofing becomes part of the concrete itself. It works even if you scratch or damage the surface later. Crystalline waterproofing lasts for the lifetime of the concrete. It is excellent for structures that hold or face water constantly.

When to use:

- Water tanks and reservoirs

- Swimming pools

- Basements with groundwater pressure

- Concrete foundations

- Tunnels and underground structures

- Sewage treatment plants

How to use:

Apply crystalline waterproofing to new or existing concrete surfaces. For new concrete, mix the crystalline powder into the concrete when making it. For existing concrete, prepare the surface by cleaning it thoroughly. Make the concrete damp but not dripping wet. Mix the crystalline powder with water to make a slurry. Brush this slurry onto the concrete surface in one or two coats. Keep the surface wet for several days after application. This helps the crystals grow properly inside the concrete. The crystals spread through the concrete and seal it completely. If cracks appear later, the crystals will grow and seal them automatically when water touches them.

7. PU Injection Waterproofing

PU injection waterproofing is a method that injects polyurethane foam or gel into cracks and gaps. Special equipment pumps the PU material under pressure into the damaged areas. The polyurethane expands many times its original size as it reacts with water. It fills every space and creates a waterproof seal. This method is perfect for fixing active leaks quickly. You can do PU injection whilst water is still leaking through. The expanding foam stops the water flow immediately. PU injection is faster and cheaper than breaking up concrete to fix leaks.

When to use:

- Active water leaks in basements

- Cracks in concrete walls or floors

- Joints between old and new concrete

- Leaking expansion joints

- Underground structures with water ingress

- Emergency leak repairs

How to use:

First, find all the cracks and leaks that need treatment. Drill small holes along the crack at regular spaces. Clean out any loose material from the crack. Insert special injection ports into the drilled holes. Connect the PU injection machine to the ports. Pump the polyurethane resin through each port in turn. The PU flows into the crack and expands to fill it completely. The foam reacts with water in the crack and becomes solid. Work from the lowest point upward so the foam pushes water out. Remove the injection ports after the PU has set. Seal the drill holes with waterproof mortar. The repaired crack is now completely waterproof.

8. Waterproofing Plaster

Waterproofing plaster is a special type of plaster that contains waterproofing chemicals mixed into it. It looks and applies like normal plaster but repels water when it dries. The water sealing ingredients create a barrier that stops moisture from passing through. Waterproofing plaster is applied to exterior walls to protect them from rain. It also works on interior walls in damp areas. The plaster provides both a smooth finish and water protection in one step. It is cheaper and faster than applying normal plaster followed by waterproofing coatings.

When to use:

- External walls exposed to rain and weather

- Retaining walls that face soil moisture

- Bathroom and kitchen walls

- Damp walls in old buildings

- Areas with rising damp problems

- Walls around water tanks

How to use:

Clean the wall surface and remove any loose or damaged plaster first. Make the wall slightly damp before applying waterproofing plaster. Mix the waterproofing plaster powder with clean water as instructed. Stir it thoroughly until smooth with no lumps. Apply the plaster with a trowel in a thin, even layer. Build up the thickness in two or three coats. Let each coat dry partially before adding the next one. Smooth the final coat to give a good finish. Keep the plaster damp for a few days by spraying water on it. This helps it cure properly and develop full waterproofing strength. The finished wall resists water whilst still allowing the wall to breathe.

9. Waterproof Coatings and Paints

Waterproof coatings and paints are special paints that create a water-resistant barrier on surfaces. They contain polymers and chemicals that repel water when dry. These coatings look like normal paint but provide waterproofing protection as well. They come in many colours so you can protect and decorate at the same time. Waterproof coatings are the easiest waterproofing method for most people to use. You apply them just like regular paint with a brush or roller. They work well for light waterproofing needs and protecting against dampness.

When to use:

- Interior bathroom and kitchen walls

- Exterior walls facing rain

- Concrete surfaces needing light protection

- Areas with minor dampness issues

- Decorative waterproofing for visible surfaces

- Quick waterproofing solutions

How to use:

Prepare the surface by cleaning it thoroughly and removing old flaking paint. Fill any cracks or holes with suitable filler. Let the filler dry completely before painting. Stir the waterproof paint well before use. Apply a primer coat if recommended by the manufacturer. Paint the first coat evenly across the whole surface. Use a brush for edges and corners, and a roller for large flat areas. Let the first coat dry for the time shown on the tin. Apply a second coat in the opposite direction to the first. Add a third coat for areas needing extra protection. Keep the painted surface dry until fully cured. Waterproof paint typically lasts three to five years before needing to be reapplied.

Why Is Waterproofing Important?

Waterproofing is important because it protects buildings from water damage and keeps them strong and safe. Water can destroy concrete, wood and metal over time. It causes cracks, mould and weakens the structure of buildings. Without waterproofing, homes and buildings develop serious problems that cost lots of money to fix. Waterproofing saves money by preventing expensive repairs later. It keeps buildings dry and comfortable to live in. Good waterproofing makes buildings last much longer. It protects your investment and keeps everyone inside healthy and safe from dampness and mould.

Why Is Waterproofing Important in the Industrial Sector?

Waterproofing is important in industrial sector because factories and warehouses store valuable equipment and products. Water leaks can damage expensive machinery and ruin stored goods. Industrial buildings often have large flat roofs that collect rainwater. Without proper waterproofing, this water seeps inside and causes production to stop. Water damage in factories costs businesses thousands of pounds in lost time and repairs. Chemical factories need water sealing to contain hazardous materials safely. Food processing plants require waterproofing to maintain hygiene standards and prevent contamination.

Industrial waterproofing protects workers and keeps operations running smoothly every day. Water on factory floors creates dangerous slipping hazards for employees. Damp conditions damage electronic equipment and control systems. Waterproof coating prevents rust and corrosion on metal structures and machinery. It stops water from reaching electrical systems and causing fires or power failures. Good waterproofing in industrial buildings means fewer shutdowns and repairs. This saves businesses money and keeps production targets on schedule. Industrial waterproofing is essential for safety, efficiency and protecting valuable assets from water damage.

Why Is Waterproofing Important in Commercial Sector?

Waterproofing is important in commercial sector because shops, offices and restaurants need to stay dry and professional. Water leaks damage stock, furniture and equipment in commercial buildings. Customers do not want to shop in damp, mouldy stores. Office workers cannot work properly in buildings with water problems. Water stains on ceilings and walls look unprofessional and drive customers away. Commercial buildings often have multiple floors, so leaks affect many businesses at once. Waterproofing protects the building owner’s investment and the tenants’ businesses from expensive water damage.

Commercial waterproofing maintains property values and attracts good tenants to buildings. Shopping centres need waterproofing to protect expensive fit-outs and stock. Hotels require waterproofing in bathrooms to prevent water damaging rooms below. Restaurants need waterproofing in kitchens to meet health and safety standards. Car parks under buildings must be waterproofed to stop water reaching lower levels. Water damage forces businesses to close temporarily, losing income every day. Insurance costs increase when buildings have poor waterproofing and frequent claims. Good water resistance treatment keeps commercial buildings operating smoothly and maintains their reputation and value.

Why Is Waterproofing Important in the Residential Sector?

Waterproofing is important in residential sector because homes are where families live and feel safe. Water leaks make homes unhealthy places with mould and dampness. Children and elderly people suffer from respiratory problems in damp houses. Water damage ruins furniture, carpets and personal belongings that families treasure. Leaking roofs and walls let rain inside and damage everything. Wet basements become unusable spaces full of mould and bad smells. Waterproofing protects families’ biggest investment and keeps their homes comfortable and dry for many years.

Residential waterproofing prevents expensive repairs and maintains home values for resale. Bathrooms and kitchens need waterproofing to stop water leaking into other rooms. Balconies require waterproofing to prevent water damaging apartments below. Foundations must be waterproofed to keep groundwater from entering homes. Rising damp destroys plaster, paint and decorations in ground floor rooms. Water damage reduces property values and makes homes difficult to sell. Banks do not lend money for homes with serious water problems. Good waterproofing gives families peace of mind knowing their home stays dry and safe through all weather conditions.

Why Singapore’s Climate Makes Waterproofing Critical?

Singapore has frequent heavy rain and very wet usage in toilets/bathrooms, which has led to widespread water ingress defects in public housing and other buildings. Many failures occurred because designs were copied from temperate countries and were not robust enough for tropical rain and usage habits.

A study from MDPI, entitled “Climate Change Projection and Its Impacts on Building Façades in Singapore”, showed that Climate projections for Singapore suggest faster deterioration of façades, sealants and coatings in future, through corrosion, adhesion failure and persistent dampnes.

For tropical high‑rise buildings, water is described as “the most severe problem”, with leaks through slabs, roofs and wet rooms a major cause of defects. Any concrete surface regularly exposed to rain, ponding water, wet cleaning, or in contact with soil is treated as needing a waterproofing system for durable performance. Studies on Singapore public housing and other buildings report recurrent leakage problems when design, installation, and maintenance are not adapted to local climate and use patterns

Where Do You Need Waterproofing in a Building?

We use waterproof in a building in many different areas to protect it from water damage. Bathrooms and toilets need waterproofing because water splashes everywhere daily. Kitchens require waterproofing around sinks and wet areas. Roofs must be waterproofed to stop rain from leaking inside. Balconies face rain and need strong waterproofing protection. Basements sit underground where groundwater pushes against walls constantly. External walls need waterproofing to keep rain out. Swimming pools and water tanks hold water and must be completely sealed. Underground car parks and tunnels require waterproofing against soil moisture. Every building needs waterproofing in these key areas to stay dry and safe.

- Toilet & Bathroom Waterproofing

Toilet and bathroom waterproofing protects these wet areas from constant water exposure every day. Bathrooms get splashed with water from showers, baths and sinks. Water sits on floors and runs down walls constantly. Without waterproofing, this water soaks through floors and damages rooms below.

A study from Emerald Insight, entitled “Waterproofing integrity and water tightness of buildings in the tropic”, showed that frequent heavy rain, very high humidity and intensive water use in toilets/bathrooms lead to rapid failure of conventional waterproofing details copied from temperate countries.

- Kitchen Waterproofing

Kitchen waterproofing is protecting kitchen areas from water damage around sinks, dishwashers and wet zones. Kitchens use lots of water for cooking, washing and cleaning every day. Water splashes from sinks onto floors and walls regularly. Dishwashers and washing machines sometimes leak or overflow. Kitchen waterproofing prevents this water from damaging the building structure. It stops water from seeping through floors to rooms below. Good waterproofing keeps kitchens hygienic and prevents mould growth in damp areas. A study from the Scientific Research Center entitled “Identifying Customer Satisfaction Indicators for the Design, Production, and Implementation of the New Generation of Kitchen Cabinets with Waterproof Seams and Moisture Resistance” showed that moisture resistance and waterproof seams significantly improve customer satisfaction in modern kitchen cabinets. Key factors include durable materials, innovative design, ease of cleaning, and long-term performance, emphasizing the importance of effective kitchen waterproofing in enhancing product quality and user experience.

- Roof Waterproofing

Roof waterproofing protects the top of buildings from rain, snow and weather. Roofs face direct sunlight, heavy rain and strong winds every day. Water must run off roofs quickly without leaking inside. Flat roofs collect water in puddles that push through weak spots. Sloped roofs shed water faster but still need waterproofing at joints. Roof waterproofing prevents leaks that damage ceilings, walls and everything inside buildings. It is one of the most important waterproofing jobs in any building. A study from MDPI, entitled “Developing a Waterproofing Decision-Making Model for High-Rise Building Projects in the Tropics,” published 22 November 2024, showed that frequent leakage and water ingress, especially at roofs, façades, toilets and bathrooms.

- Balcony Waterproofing

Balcony waterproofing protects outdoor spaces attached to buildings from rain and weather damage. Balconies face rain, sun, wind and foot traffic all the time. Water collects on balcony floors and can leak into rooms below. Without waterproofing, balconies develop cracks and water seeps through. This damages apartments or rooms underneath the balcony. Balcony waterproofing creates a sealed surface that drains water away safely. It protects the balcony structure and prevents expensive damage to the building. A study from Forest Service Research and Development (R&D)entitled “Durable solutions for balconies and decks” showed that wood-framed balconies and decks in multifamily buildings are highly vulnerable to moisture damage. Past structural failures show that poor design, construction defects, and inadequate balcony waterproofing significantly increase the risk of water infiltration, deterioration, and potential structural collapse.

- Basement Waterproofing

Basement waterproofing protects underground rooms from groundwater and soil moisture that push against walls constantly. Basements sit below ground level where water collects naturally in soil. Heavy rain makes groundwater levels rise even higher. This water pressure forces moisture through basement walls and floors. Without waterproofing, basements become damp, mouldy and unusable spaces. Basement waterproofing keeps these areas dry so families can use them safely. It protects the building’s foundation and prevents structural damage. A study from Henry Stewart Talks Ltd (HSTalks) entitled “Ground water assessment and the design of basement waterproofing”, showed that Effective basement waterproofing requires thorough groundwater risk assessment to ensure cost efficiency and long-term durability. Proper drainage design, contamination evaluation, and gas risk analysis are essential, especially below groundwater levels. Professional assessment helps prevent hydrostatic pressure issues, vapour intrusion, and system failure in contaminated environments.

- Wall & Exterior Waterproofing

Wall and exterior waterproofing protects outside walls from rain, wind and moisture damage. External walls face harsh weather conditions every day throughout the year. Rain beats against walls and tries to soak through. Wind drives rain into tiny cracks and gaps. Rising damp pulls moisture up from the ground into walls. Exterior waterproofing creates a protective barrier that keeps walls dry. It prevents water from entering the building whilst letting walls breathe. Good exterior waterproofing makes buildings last longer and stay healthy. A study from E3S Web of Conferences entitled “A Review of Exterior Waterproofing Technologies in Prefabricated Buildings”, showed that current exterior wall waterproofing technologies for prefabricated buildings, including membranes, sealants, grouting, coatings, and waterproof concrete. It evaluates their advantages and limitations, highlighting the need for advanced materials and experimental comparisons to improve long-term waterproof performance of external walls.

- Swimming Pool Waterproofing

Swimming pool waterproofing creates a completely watertight seal to hold thousands of litres of water safely. Pools hold water under constant pressure against walls and floors all year round. Even tiny leaks waste water and damage the pool structure. Chlorine and pool chemicals attack concrete and can cause damage over time. Swimming pool waterproofing must resist water pressure, chemicals and constant exposure. It keeps water in the pool and prevents it from leaking into surrounding ground. Proper waterproofing is essential for every swimming pool to function properly. A study from Springer Nature Limited entitled “Technical and Sustainability Analysis of Construction Processes and Covering Systems for Outdoor Swimming Pools” showed that construction methods and covering systems for outdoor swimming pools, highlighting key factors such as design, soil conditions, durability, cost, and sustainability. The findings support informed decision-making and emphasize the importance of proper swimming pool waterproofing for long-term performance and environmental efficiency.

- Water Tank Waterproofing

Water tank waterproofing seals tanks to store clean drinking water safely without leaks or contamination. Water tanks hold water for houses and buildings to use every day. Tanks face constant water pressure from inside pushing outward on walls. Leaking tanks waste precious water and can contaminate stored water with dirt. Tank waterproofing must be food-safe and not release harmful chemicals into water. It creates a complete seal that holds water whilst keeping the tank structure strong. Proper waterproofing ensures tanks provide safe, clean water for many years.

- Underground Structures Waterproofing

Underground structures waterproofing protects car parks, tunnels, basements and foundations from groundwater and soil moisture. These structures sit completely below ground level surrounded by wet soil. Groundwater pushes against walls and floors with very strong pressure constantly. Underground areas also face water from rain that soaks down through soil. Without proper Impermeabilization, water floods into these spaces and causes serious damage. Underground waterproofing creates strong barriers that keep structures completely dry. It must withstand high water pressure for many decades.

What’s The Difference Between Waterproofing vs. Re-tiling?

The difference between waterproofing and re-tiling is that waterproofing creates a protective barrier under tiles whilst re-tiling just replaces the tiles on top. This is a list of Waterproofing and re-tiling that make them unique.

| Aspect | Waterproofing | Re-tiling |

|---|---|---|

| What it does | Creates a barrier to block water | Replaces old tiles with new ones |

| Where it goes | Under the tiles on floors and walls | On top of the waterproofing layer |

| Main purpose | Stops water leaks and damage | Makes surfaces look nice and clean |

| Visibility | Hidden underneath, you cannot see it | Visible surface that everyone sees |

| Fixes leaks | Yes, stops water from passing through | No, does not stop leaks at all |

| Cost | Moderate to expensive | Moderate cost for materials and labour |

| How long it lasts | 10-25 years with good installation | 15-20 years if installed properly |

| When needed | When leaks occur or during construction | When tiles crack, break or look old |

What’s The Difference Between Waterproofing and Sealing?

The difference between waterproofing and sealing is that waterproofing creates a complete barrier against all water whilst sealing fills gaps and cracks. This is a list of Waterproofing and Sealing that make them unique.

| Aspect | Waterproofing | Sealing |

|---|---|---|

| What it does | Blocks water across entire surfaces | Fills gaps, cracks and joints |

| Coverage area | Large areas like whole floors and walls | Small areas like edges and corners |

| Materials used | Membranes, coatings and special systems | Silicone, polyurethane and rubber sealants |

| Main purpose | Stops water soaking through materials | Stops water entering through openings |

| Application | Applied in layers across surfaces | Applied to specific joints and gaps |

| Protection level | Complete water barrier | Extra protection at weak points |

| Where used | Bathrooms, basements, roofs, balconies | Around baths, sinks, windows, doors |

| Working together | Provides main protection | Adds extra protection to waterproofing |

What is the Difference Between Waterproofing and Water Resistant?

The difference between waterproofing and water resistant is that waterproofing blocks water completely whilst water resistant only slows water down temporarily. This is a list of Waterproofing and Water-resistant that make them unique.

| Aspect | Waterproofing | Water Resistant |

|---|---|---|

| Water blocking | Blocks water completely | Slows water down temporarily |

| Duration | Works indefinitely when wet | Fails after prolonged water exposure |

| Protection level | 100% protection against all water | Partial protection from light moisture |

| Best use | Constant water exposure areas | Occasional dampness areas |

| Examples | Bathroom floors, swimming pools, basements | Exterior walls, raincoats, outdoor furniture |

| Water pressure | Handles high water pressure | Cannot handle strong water pressure |

| Cost | More expensive materials and installation | Cheaper and easier to apply |

| Effectiveness | Keeps areas completely dry always | May eventually leak in heavy water |

How Much Does Waterproofing Cost in Building Singapore?

Waterproofing cost in building in Singapore varies depending on the area size and method you choose. Small bathroom waterproofing typically costs between SGD $500 to $2,000. Larger areas like balconies cost SGD $1,000 to $3,500. Basement waterproofing is more expensive, ranging from SGD $3,000 to $10,000. Roof waterproofing costs SGD $8 to $30 per square metre. The type of waterproofing material affects the price significantly. Premium materials like polyurethane cost more than basic cementitious waterproofing.

Factors affecting waterproofing costs include:

- Size of the area needing waterproofing

- Type of waterproofing material chosen

- Complexity of the job and access difficulty

- Condition of existing surfaces

- Labour costs and contractor experience

- Additional repairs needed before waterproofing

How Many Days Does Waterproofing Take?

Waterproofing take different amounts of time depending on the area size and waterproofing method used. Small bathrooms usually take 2 to 4 days to waterproof completely. This includes preparation, application and drying time. Larger balconies need 3 to 5 days for proper waterproofing. Basements can take 5 to 10 days because of their size. Roofs might need 1 to 2 weeks depending on weather conditions. Each waterproof coating layer needs time to dry before adding the next coat.

Timeline for different waterproofing projects:

- Bathroom: 2 to 4 days

- Kitchen wet areas: 2 to 3 days

- Balcony: 3 to 5 days

- Basement: 5 to 10 days

- Roof: 7 to 14 days

- Swimming pool: 10 to 21 days

FAQs About Understanding Waterproofing in Building

Waterproof paint is the cheapest method of waterproofing for buildings. It costs less than other methods and is easy to apply yourself. However, waterproof paint provides only basic protection against dampness. It works well for minor moisture issues but not for areas with heavy water exposure or pressure.

The dry season is the best time to do waterproofing of your home. Waterproofing works best when surfaces are completely dry and weather stays sunny. Avoid rainy seasons as moisture affects waterproofing application and curing. Plan waterproofing during good weather for best results and faster completion times.

Every 5 to 10 years often you should reapply waterproofing depending on the type and area. High-traffic areas like balconies need reapplication sooner. Quality waterproofing with proper maintenance lasts longer. Inspect waterproofing regularly and reapply when you notice cracks, peeling or leaks developing anywhere.

Cementitious waterproofing type of waterproofing is best for walls in most situations. It bonds strongly to concrete and brick walls. Liquid membrane waterproofing also works excellently on exterior walls. For internal walls facing dampness, waterproof paint or plaster provides good protection. Choose based on your wall type and water exposure.

You can waterproof over old waterproofing, but the previous layer must be intact and undamaged. Surface preparation is essential to remove debris or peeling material for a strong, effective new application.

Classic Waterproofing & Plumbing (s) Pte Ltd is best for waterproofing service. They provide expert services using high-quality materials and techniques to ensure long-lasting protection, prevent costly water damage, and maintain structural integrity.