Waterproofing materials are crucial in protecting buildings from water damage. They create a barrier that prevents water from seeping into the structure, safeguarding foundations, walls, and roofs. There are various types of waterproofing materials, each designed for specific applications, such as bitumen for roofs or cementitious coatings for basements. These materials ensure long-lasting protection, reducing the risk of mould, corrosion, and structural weakening. Proper waterproofing not only extends the lifespan of buildings but also saves costs by preventing costly water damage repairs.

What Is Waterproofing Material?

Waterproofing material is a special substance that stops water from getting through. People use it to keep things dry and safe from water damage. Builders put it on roofs, walls, and floors. It acts like a shield against rain, moisture, and leaks. This material helps protect our homes, schools, and buildings from water problems.

We can find moisture-resistant material in many forms. Some look like thick paint, whilst others come as sheets or rolls. A study from Research Gate, entitled “Analysis of Water-Proof Properties of Building Waterproof Materials and Concrete Components”, shows that cement-based coatings improve anti-seepage performance, polyurethane coatings provide superior sealing by closing micropores and cracks, and SBS copolymer membranes form dense waterproof layers through hot-melt bonding. The study concludes that all three materials offer effective waterproofing, but proper material selection and construction methods are essential to enhance building durability, safety, and service life., showed that recurrent leakage problems occur when design, installation, and maintenance are not adapted to local climate and use patterns.

A study from Science Direct entitled “Investigating Effective Waterproofing Materials in Preventing Roof Leaking; Initial Comparative Study: Malaysia, U.K”, showed that some waterproofing products distributed in Malaysia originate from companies with operations in Singapore, reflecting the use of globally engineered systems suited to tropical climates. For Singapore, this suggests that selecting high-quality, internationally tested waterproofing materials is critical to improving durability, preventing roof leakage, and ensuring long-term building performance.

What Are the Types of Waterproofing Materials?

The different types of cementitious waterproofing include bitumen, cementitious, polyurethane (PU), EPDM (ethylene propylene diene monomer), PVC waterproofing membranes, TPO (thermoplastic olefin), rubberised asphalt, crystalline, geotextile, and acrylic options.

1. Bitumen Waterproofing

Bitumen waterproofing uses thick tar-like material to create strong waterproof barriers on building surfaces. Bitumen comes from petroleum and has been used for waterproofing for over a hundred years. It is completely waterproof and very durable in harsh conditions. Bitumen waterproofing comes in two main forms: liquid bitumen you paint on and bitumen sheets you stick down. Both create tough barriers that resist water, chemicals and soil pressure. Bitumen works especially well underground where it faces constant groundwater. It is one of the most reliable waterproofing methods for foundations and basements.

A study from the American Society of Civil Engineers (ASCE) entitled “Investigation of Antiaging Performance and Service Life of OMMT/SBS Modified Bitumen Waterproof Membranes”, showed that Adding 3% organic montmorillonite (OMMT) to SBS-modified bitumen improves aging resistance, thermal performance, and network structure, reducing chemical degradation. This enhancement extends the service life of bitumen waterproof membranes from 16.9 to 21.3 years, ensuring long-lasting waterproofing protection.

When to use:

- Building foundations and basement walls

- Underground car parks and structures

- Flat roofs on commercial buildings

- Bridge decks and infrastructure

- Areas with high water pressure

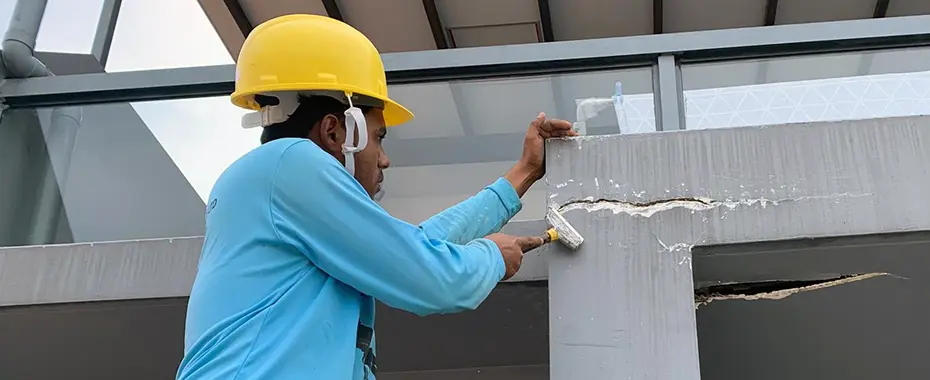

2. Cementitious Waterproofing

Cementitious waterproofing is a cement-based coating that makes surfaces waterproof when applied. It contains waterproof cement, sand and special chemicals mixed with water. Cementitious coatings mixture is applied like plaster to walls and floors. A study from Scite, entitled “Development of Polymer Modified Cement Mortars for Waterproof”, shows that polymer-modified cement mortars for waterproofing, focusing on their raw materials, properties, and performance improvements. It analyzes how different polymer–cement ratios affect compressive and flexural strength, and explains the mechanisms by which super mineral powder and re-dispersible polymer powders enhance impermeability, durability, and adhesion.

When to use:

- Bathrooms and shower areas

- Water tanks and swimming pools

- Basements and underground structures

- Wet balconies and terraces

- Foundations below ground level

3. Polyurethane (PU) Waterproofing

Polyurethane (PU) waterproofing is a highly flexible waterproofing method using elastic polyurethane materials. Polyurethane is a strong rubber-like material that stretches and moves with surfaces. It resists chemicals, weather, UV damage and wear very well. PU waterproofing comes as liquid that you apply to surfaces. It dries to form a seamless rubber-like waterproof coating. This coating can expand and contract without cracking or breaking. PU waterproofing lasts for many years even in harsh outdoor conditions. It is more expensive than other methods but provides excellent flexible protection.

A study from Wiley Online Library entitled “A polyurethane elastomer combining high strength and excellent self-healing properties for waterproofing coatings”, a high-strength, self-healing polyurethane (PUGI-D3B2) with enhanced hydrogen bonding. It restores 98% of mechanical strength after damage and can be applied in waterproof coatings, offering durable, multifunctional solutions for PU waterproofing applications.

When to use:

- Roofs exposed to sun and rain

- Parking areas and driveways

- Industrial floors with heavy use

- Balconies and terraces

- Areas requiring long-lasting flexible protection

4. EPDM (Ethylene Propylene Diene Monomer)

EPDM (Ethylene Propylene Diene Monomer) waterproofing uses synthetic rubber sheets for roofing and waterproofing applications. EPDM is a very flexible rubber material that stretches and seals surfaces tightly. It resists sun damage, ozone, weather and temperature extremes excellently. EPDM sheets come in large rolls that cover roofs with few seams. The rubber is black and very durable lasting 30 years or more. EPDM is popular for flat roofs on commercial and residential buildings. It is easy to install and requires minimal maintenance over its lifetime.

A study from MDPI entitled “A Review of EPDM (Ethylene Propylene Diene Monomer) Rubber-Based Nanocomposites: Properties and Progress”, showed that Ethylene propylene diene monomer (EPDM) waterproofing benefits from nanotechnology, which enhances tensile, chemical, thermal, and electrical properties. Nanomaterials in EPDM improve durability and flexibility, making it a high-performance solution for long-lasting waterproofing applications.

When to use:

- Flat roofs on houses and commercial buildings

- Large roof areas needing quick installation

- Areas with extreme temperature changes

- Green roofs and roof gardens

- Buildings needing long-lasting roof protection

5. PVC Waterproofing Membranes

PVC waterproofing membranes are plastic sheet materials used for waterproofing roofs and structures. PVC stands for polyvinyl chloride, a strong flexible plastic. These membranes come in rolls and are welded together with heat. PVC membranes are white or light coloured reflecting sun heat. They resist chemicals, oils and most weathering very well. PVC waterproofing is very popular for flat roofs on buildings. The seams are heat-welded creating strong watertight joints. PVC membranes last 20 to 30 years with proper installation and care.

A stud from MDPI entitled “Durability and Degradation of PVC-P Roofing Membrane—Example of Dynamic Fatigue Testing”, showed that 11-year-old PVC-P waterproofing membranes revealed degradation due to polymer dehydrochlorination. Mechanical properties often remain within standards, but cyclic dynamic fatigue and SEM/EDS analysis can detect deterioration, highlighting risks for roof watertightness, liability, and warranty claims.

When to use:

- Flat roofs on commercial buildings

- Hospital and clean room roofs

- Balconies and podium decks

- Plaza decks and terraces

- Buildings needing reflective white roofing

6. TPO (Thermoplastic Olefin) Membranes

TPO (Thermoplastic Olefin) membranes are white plastic sheets used for waterproofing flat roofs. TPO is a blend of rubber and plastic materials creating flexible membranes. These membranes reflect sunlight helping buildings stay cooler in summer. TPO resists UV damage, ozone and chemical exposure very well. The sheets are heat-welded together like PVC membranes. TPO is newer than PVC but growing popular for roofing. It combines benefits of rubber and plastic waterproofing materials. TPO membranes typically last 20 to 25 years with good performance.

When to use:

- Commercial flat roofs and buildings

- Schools and institutional buildings

- Roofs needing energy-efficient white coating

- Large roof areas requiring quick installation

- Buildings in hot climates needing cooling

7. Rubberized Asphalt

Rubberized asphalt is a waterproofing material combining asphalt with rubber polymers for flexibility. It comes as thick self-adhesive sheets or liquid that you apply. Rubberized asphalt sticks to surfaces without heat unlike traditional bitumen. The rubber makes it flexible so it stretches with building movement. It creates very strong waterproof barriers that last for decades. Rubberized asphalt works excellently on foundations, basements and roofs. The material is black and very sticky when fresh. It provides reliable protection in challenging underground and exposed conditions.

When to use:

- Foundation walls and basements

- Below-grade waterproofing applications

- Roof underlayment beneath tiles or shingles

- Bridge decks and infrastructure

- Areas needing flexible adhesive waterproofing

8. Crystalline Waterproofing

Crystalline waterproofing is a chemical treatment that grows crystals inside concrete making it waterproof. Special chemicals react with moisture and cement in concrete. They form millions of tiny crystals that fill all pores and cracks. These crystals block water but still let concrete breathe. Crystalline waterproofing becomes part of the concrete permanently. It works even if you damage the surface later. The crystals continue growing whenever water touches concrete. Crystalline waterproofing lasts for the entire lifetime of concrete structures. It is excellent for water tanks, basements and structures holding water.

When to use:

- Water tanks and reservoirs

- Swimming pools and water features

- Basements with groundwater pressure

- Concrete foundations and structures

- Sewage treatment plants and tunnels

9. Geotextile Membranes

Geotextile membranes are fabric-like sheets used in waterproofing and drainage systems. They are made from synthetic fibres woven or bonded together. Geotextiles separate, filter and protect waterproofing layers from damage. They allow water to drain through whilst blocking soil particles. Geotextile membranes protect waterproofing from stones, roots and sharp objects. They are often used with other waterproofing systems for complete protection. Geotextiles come in different thicknesses for various applications. They are essential for underground and landscape waterproofing projects.

When to use:

- Protecting basement waterproofing from backfill damage

- Drainage systems around foundations

- Under gravel and drainage layers

- Green roofs and planter boxes

- Landscape and retaining wall drainage

10. Acrylic Waterproofing

Acrylic waterproofing uses acrylic polymer coatings to create flexible waterproof barriers on surfaces. Acrylic is a water-based material that is easy to apply. It forms a flexible rubber-like coating when dry. Acrylic waterproofing resists UV damage better than many other types. It is available in different colours for visible applications. Acrylic coatings are environmentally friendly with low chemical smell. They work well on roofs, balconies and exterior surfaces. Acrylic waterproofing is popular for residential applications and easy maintenance.

A study conducted Korea Science entitled “A Study on the Crack Response and Waterproof Properties of High-Functional Water-Based Acrylic Paints for Exterior Walls” showed that specially developed elastic acrylic waterproof paint outperforms general water-based paint, providing up to 10× better crack response, strong adhesion (≥1.3 MPa), and resistance to 0.1 MPa water pressure, ensuring improved watertightness for concrete walls.

When to use:

- Flat roofs and roof terraces

- Balconies and external walkways

- Painted surfaces needing waterproofing

- Areas requiring UV-resistant protection

- Residential waterproofing projects

Why Do Buildings Need Waterproofing Material?

Buildings need waterproofing material to protect structures from water damage, leaks and moisture problems. Water is one of the biggest enemies of buildings causing serious damage over time. Without damp-proofing, water seeps through walls, roofs and floors destroying everything. Waterproofing materials create protective barriers that keep buildings completely dry. They prevent expensive repairs, health problems and structural failures. Buildings need waterproofing to last longer and stay safe for families.

Key reasons buildings need waterproofing materials:

- Prevents water leaks through roofs, walls and floors

- Stops dampness and mould growth inside buildings

- Protects concrete, wood and metal from decay

- Maintains structural strength and stability

- Keeps indoor spaces healthy and comfortable

- Reduces maintenance and repair costs significantly

- Protects belongings and equipment from water damage

- Increases property value and saleability

- Prevents electrical problems from moisture

- Extends building lifespan by decades

Where to Use Waterproofing Material in Your Space?

Use waterproofing material in bathrooms, kitchens, basements, roofs, balconies and foundations of your building. Bathrooms need waterproofing on floors and walls to stop water leaking through. Kitchen wet areas around sinks require waterproofing for protection. Basements face groundwater so need complete waterproofing on walls and floors. Roofs must have waterproofing to keep rain out of buildings. Balconies and terraces need waterproofing as they face weather directly. Building foundations require waterproofing against soil moisture. Water tanks and swimming pools need waterproofing to hold water safely. External walls benefit from waterproofing against rain. Use waterproofing materials wherever water touches your building regularly.

Waterproofing Material for Roof

Waterproofing material for roof includes membranes, coatings and sheets that protect roofs from rain and weather. Roof waterproofing uses materials like bitumen sheets, PU coatings, EPDM rubber and liquid membranes. These materials create complete barriers that stop all water from entering buildings. Roofs face direct sun, heavy rain and extreme temperatures daily. Waterproofing materials must resist UV damage, heat and cold effectively. They keep buildings dry by shedding water quickly off roof surfaces. Quality roof waterproofing lasts 15 to 25 years with proper installation.

When to use:

Use waterproofing material for roof on all new roof construction projects. Apply when replacing old damaged roofs that leak. Use on flat roofs where water collects in puddles. Apply before installing roof gardens or solar panels. Use when roof shows signs of leaks or water damage.

How to use:

Clean the roof surface completely removing all debris and dirt. Repair cracks and damaged areas in the roof structure first. Make sure roof has proper slope for water drainage. Apply primer to help waterproofing stick to roof surface. For liquid membranes, brush or roll on first coat evenly. Add reinforcement fabric whilst first coat is still wet. Apply second and third coats over the fabric layer. For sheet membranes, unroll them across roof carefully. Stick sheets down with adhesive or heat welding properly. Overlap all joints by at least 10 centimetres. Seal edges, corners and around roof penetrations completely.

Waterproofing Materials for Walls

Waterproofing materials for walls include coatings, membranes and treatments that protect walls from moisture and rain. Wall waterproofing uses materials like cementitious coatings, acrylic paints, bitumen and liquid membranes. Sealant coating materials create barriers that stop water from soaking through walls. External walls face rain, wind and humidity constantly. Internal walls in bathrooms need waterproofing against splashes and steam. Waterproofing materials keep walls dry preventing dampness, mould and structural damage. They also improve indoor air quality by stopping moisture.

When to use:

Use damp-proofing materials for walls on external walls facing heavy rain. Apply on bathroom walls especially in shower areas. Use on basement walls below ground level. Apply on retaining walls holding back soil and water. Use when walls show damp patches or water stains.

How to use:

Clean walls thoroughly removing dirt, loose paint and debris completely. Repair all cracks and holes with suitable filler first. Let walls dry completely before applying waterproofing materials. Apply primer coat if the product requires it. Brush or spray waterproofing material evenly across wall surface. Make sure coverage is complete with no thin spots anywhere. Apply multiple coats as recommended by manufacturer instructions. Pay extra attention to corners and joints between surfaces. Let each coat dry completely before adding next layer. For basement walls, apply thicker waterproofing or use membrane systems. Finish with protective render or paint if needed.

Waterproof Ceiling Material

Waterproof ceiling material includes special paints, boards and coatings that protect ceilings from water leaks above. Ceiling waterproofing uses materials like waterproof gypsum boards, PVC panels and acrylic coatings. These materials resist water damage from roof leaks or bathroom leaks above. Waterproof ceiling materials prevent water stains, mould growth and ceiling collapse. They are especially important in bathrooms, kitchens and top floor rooms. Waterproof ceilings maintain appearance and prevent health problems from dampness. They provide extra protection when waterproofing above fails temporarily.

When to use:

Use waterproof ceiling material in bathrooms below other bathrooms. Apply in kitchens and wet areas of buildings. Use on top floor ceilings under roofs. Apply in basements with groundwater seepage. Use when ceilings show water stains or dampness.

How to use:

Install waterproof gypsum boards instead of regular boards during construction. Make sure boards are properly rated for wet areas. Seal all joints between boards with waterproof tape and compound. For existing ceilings, apply waterproof coating or paint. Clean ceiling surface removing all dust and loose material. Repair any cracks or damage before waterproofing starts. Apply waterproof primer coat first if recommended. Brush or roll on waterproof paint in two coats. Make sure coverage is even across entire ceiling surface. Let first coat dry completely before applying second coat. Check regularly for any new leaks or damage above.

Waterproof Material for Bathroom

Waterproof material for bathroom includes liquid membranes, cementitious coatings and sheet systems for complete protection. Bathroom waterproofing uses materials like polyurethane, acrylic membranes and waterproof cement. These materials create sealed barriers on bathroom floors and walls. Bathrooms face constant water exposure from showers, baths and sinks daily. Waterproof materials prevent water from leaking to rooms below. They stop mould growth and keep bathrooms healthy and safe. Quality bathroom waterproofing lasts 10 to 15 years with proper installation.

When to use:

Use waterproof material for bathroom in all new bathroom construction. Apply when renovating old bathrooms completely. Use after discovering leaks or water damage. Apply before installing tiles on floors and walls. Use in shower areas and around bathtubs always.

How to use:

Clean bathroom floors and walls completely removing all dirt. Remove old tiles and damaged material if renovating. Fill all cracks and gaps with waterproof filler first. Apply primer coat if your waterproofing product requires it. Brush or roll liquid waterproofing membrane onto floors first. Pay special attention to corners where walls meet floors. Add reinforcement tape over all joints and corners. Apply waterproofing up walls to at least 30 centimetres high. In shower areas, waterproof walls up to 180 centimetres high. Apply two or three coats letting each dry completely. Test waterproofing by spraying water before installing tiles.

Toilet Waterproofing Materials

Toilet waterproofing materials include liquid membranes, cementitious coatings and sealants that protect toilet areas completely. Toilet waterproofing uses materials like polyurethane membranes, waterproof cement and epoxy coatings. These materials seal floors and walls around toilets preventing water leaks. Toilets face water splashes, cleaning and constant moisture daily. Waterproofing materials stop water from damaging floors and seeping to rooms below. They prevent hygiene problems, mould growth and unpleasant smells. Proper toilet waterproofing creates clean, safe and dry toilet spaces.

When to use:

Use toilet waterproofing materials in all new toilet construction. Apply when renovating or repairing old toilets. Use after discovering leaks around toilet areas. Apply before installing tiles or flooring. Use around toilet fixtures and floor drains always.

How to use:

Clean toilet floor and walls thoroughly removing all dirt. Fill cracks and level the floor properly first. Apply primer coat to help waterproofing stick better. Brush liquid waterproofing membrane onto entire floor area. Apply waterproofing up walls by at least 15 centimetres. Pay extra attention around toilet fixture mounting points. Add reinforcement tape over floor-wall joints and corners. Seal around floor drain with extra waterproofing layers. Apply at least two coats for complete protection. Let each coat dry before applying the next one. Test by spraying water before installing tiles or fixtures.

How Do You Choose the Right Waterproofing Material?

How do you choose the right waterproofing material depends on several important factors about your building and needs. Consider the area you need to waterproof and how much water it faces. Think about your budget for materials and installation costs. Check if the material works with your building’s construction type. Understand how long you need the waterproofing to last. Research different materials and their performance in similar conditions. Consult professional contractors for expert recommendations on your specific situation.

Key factors for choosing waterproofing materials:

- Water exposure level: constant pressure or occasional dampness

- Surface type: concrete, wood, metal or mixed materials

- Location: basement, roof, bathroom, or external wall

- Climate conditions: hot, cold, humid or coastal areas

- Movement: flexible for moving structures or rigid for stable areas

- Budget: initial costs and long-term maintenance expenses

- Durability: how many years protection is needed

- Application method: DIY-friendly or professional installation required

- Breathability: whether surface needs to breathe or be sealed

- Chemical resistance: exposure to pool chemicals or contaminants

Different waterproofing materials suit different situations and building requirements specifically. Bathrooms work best with cementitious or liquid membrane waterproofing systems. Basements need bituminous or crystalline waterproofing for groundwater pressure resistance. Roofs require flexible membranes like PU, EPDM or TPO materials. Balconies benefit from polyurethane or acrylic waterproofing that handles movement. Swimming pools need cementitious or crystalline systems resisting chemicals and pressure. External walls use acrylic coatings or waterproofing plaster for weather protection. Choose materials proven to work in your climate and conditions.

Professional advice helps you choose waterproofing materials correctly for best long-term results. Experienced contractors assess your building and recommend suitable materials and systems. They understand which products work best in Singapore’s tropical climate conditions. Professionals consider your budget whilst ensuring adequate protection for your needs. They can spot potential problems that might affect waterproofing performance later. Getting expert guidance prevents costly mistakes from choosing wrong materials initially. Quality materials properly installed provide decades of reliable waterproof protection for buildings.

How Much Does Waterproofing Material Cost in Singapore?

Waterproofing material cost in Singapore varies widely depending on the type and quality you choose. Basic cementitious waterproofing materials cost SGD $50 to $150 for small bathroom projects. Liquid membrane waterproofing costs SGD $100 to $300 for balcony-sized areas. Sheet membrane materials cost SGD $200 to $800 depending on quality and size. Polyurethane waterproofing materials cost SGD $150 to $400 for residential applications. Bituminous waterproofing costs SGD $100 to $500 for foundation treatments. Premium materials like crystalline waterproofing cost SGD $200 to $600 per application.

Material costs by type:

- Cementitious waterproofing: SGD $50 to $150

- Liquid membranes: SGD $100 to $300

- Sheet membranes: SGD $200 to $800

- Polyurethane coating: SGD $150 to $400

- Bituminous materials: SGD $100 to $500

- Crystalline treatment: SGD $200 to $600

- Acrylic waterproofing: SGD $80 to $250

- EPDM rubber sheets: SGD $300 to $1,000

Professional installation adds significantly to total waterproofing costs in Singapore projects. Labour charges range from SGD $200 to $500 per day depending on contractor experience. Complete bathroom waterproofing costs SGD $500 to $2,000 including materials and labour. Balcony waterproofing totals SGD $1,000 to $3,500 for complete treatment. Basement waterproofing costs SGD $3,000 to $10,000 for full protection systems. Roof waterproofing charges SGD $8 to $30 per square metre installed. Although quality materials cost more initially, they provide better long-term value. Cheap materials fail quickly requiring expensive repairs and replacements later on.

How Long Does Waterproofing Material Last?

Waterproofing material lasts between 5 to 30 years in Singapore depending on type and installation quality. Cementitious waterproofing lasts 10 to 15 years in bathrooms and wet areas. Liquid membrane waterproofing lasts 15 to 20 years on balconies and roofs. Sheet membrane systems last 20 to 25 years with proper installation care. Polyurethane waterproofing lasts 15 to 20 years even in harsh outdoor conditions. Bituminous waterproofing lasts 20 to 30 years on foundations and basements. Crystalline waterproofing lasts the lifetime of concrete structures permanently.

Lifespan by waterproofing material type:

- Cementitious: 10 to 15 years

- Liquid membranes: 15 to 20 years

- Sheet membranes: 20 to 25 years

- Polyurethane: 15 to 20 years

- Bituminous: 20 to 30 years

- Crystalline: 30+ years

- EPDM rubber: 25 to 30 years

- Acrylic coating: 8 to 12 years

Waterproofing material lifespan depends on installation quality, maintenance and environmental exposure significantly. Professional installation makes waterproofing last much longer than DIY or poor workmanship. Singapore’s hot humid climate and heavy rainfall test waterproofing materials constantly. Regular inspections and small repairs extend waterproofing life by many years. Exposed waterproofing on roofs wears faster than protected systems under tiles. Good drainage reduces stress on waterproofing making it last longer. Well-maintained waterproofing often exceeds expected lifespan providing excellent long-term value. Quality materials properly installed and cared for protect buildings for decades.

FAQ’s

Waterproofing material protects a structure by creating a complete barrier that blocks all water from entering. The material seals surfaces preventing water from soaking through walls, floors and roofs. It stops moisture from reaching concrete, steel and other building materials that water damages. Waterproofing prevents cracks, corrosion and decay that weaken structures over time. It keeps buildings dry, strong and safe for many years by eliminating water penetration completely.

Bituminous and crystalline waterproofing materials are best for basements facing groundwater pressure. Bitumen creates thick barriers on basement walls that resist water and soil pressure. Crystalline waterproofing penetrates concrete growing crystals that block water permanently. Both materials handle constant moisture and high water pressure effectively. For existing basements, cementitious coatings or PU injection also work well to stop leaks and dampness problems.

Acrylic coatings and cementitious waterproofing plaster materials work for external walls facing rain and weather. Acrylic waterproofing creates flexible coatings that resist UV damage and breathe naturally. Waterproofing plaster provides both weather protection and attractive finish in one application. Silicone-based water repellents also work well on external walls for basic moisture protection. Choose materials that let walls breathe whilst blocking rain effectively.

Yes, you should use professional services to apply waterproofing material for best long-lasting results. Professionals have experience, skills and tools to install waterproofing correctly without mistakes. They know how to prepare surfaces properly and apply materials in right thicknesses. Professional installation comes with warranties protecting your investment if problems occur. Although DIY saves money initially, poor installation causes expensive failures requiring complete replacement later on.

Yes, waterproofing material can crack or fail over time from building movement or poor installation. Rigid waterproofing cracks when structures settle or shift over years. Poor surface preparation causes waterproofing to peel away and fail prematurely. UV damage, extreme weather and wear gradually break down waterproofing materials. However, quality materials professionally installed with regular maintenance last many years without cracking or failing significantly.

Yes, acrylic material is waterproof when used in proper waterproofing coatings and membranes. Acrylic waterproofing creates flexible barriers that block water completely when applied correctly. It resists UV damage and weathering better than many other waterproofing materials. Acrylic coatings work excellently for roofs, balconies and external surfaces needing waterproof protection. However, you must apply multiple coats of acrylic waterproofing for complete water blocking performance.