Cementitious waterproofing (Cement-based waterproofing) is a method used to create a strong, durable barrier against water. Ideal for concrete surfaces such as basements, swimming pools, and foundations, this technique prevents moisture from entering and causing damage. It’s easy to apply, long-lasting, and provides essential protection against water seepage.

A study from Science Direct entitled “Combined effect of rice husk ash and cementitious capillary crystalline waterproofing materials on the performance of mortar”, showed that sustainable improvements in cementitious waterproofing by using rice husk ash (RHA), an agricultural waste, as a partial cement replacement to reduce carbon emissions from cement production. RHA contains high silica content, which enhances strength, durability, and impermeability while supporting internal curing through water retention. However, excessive use may affect crack self-healing.

To address this, researchers combined RHA with a capillary crystalline waterproofing (CCCW) admixture that forms crystals within pores and cracks, improving sealing performance. Experimental results show that the combination enhances mechanical properties, reduces water absorption, and increases resistance to corrosion and chloride penetration. Optimal results depend on proper mix proportions and curing methods, with water immersion delivering better performance. The study concludes that integrating RHA and CCCW can create more durable, eco-friendly cementitious waterproofing materials suitable for modern construction.

What is Cementitious Waterproofing?

Cementitious waterproofing is a cement-based coating system that creates waterproof barriers on concrete and masonry surfaces. It contains special waterproof cement, sand and chemical additives mixed with water. This mixture is applied like plaster to walls and floors creating a hard protective layer.

Cementitious coating is one of the easiest and most affordable waterproofing methods available. It bonds very strongly to concrete, brick and stone surfaces permanently. The coating is rigid when dry so works best on stable surfaces without movement. It is extremely popular for bathrooms, water tanks, basements and swimming pools worldwide.

A study on cementitious repair mortars highlights how polymer emulsions can improve the performance of cement-based materials used in concrete protection and waterproofing. As many concrete structures age, effective repair materials must offer strong workability, durability, and resistance to cracking.

What are the Different Types of Cementitious Waterproofing?

The different types of cementitious waterproofing include rigid, flexible, crystalline, polymer-modified, single-component, and two-component options. These materials help protect buildings from water damage by creating a strong barrier against moisture.

Understanding the different types ensures effective protection for your building.

1. Rigid Cementitious Waterproofing

Rigid cementitious waterproofing is a hard cement-based coating that creates strong waterproof barriers on stable surfaces. It contains waterproof cement, sand and chemical additives without flexibility enhancers. Rigid waterproofing dries into a hard concrete-like layer that cannot stretch or bend. It works excellently on structures that do not move or shift over time.

A study from Journal of Engineering Science and Technology Review (JESTR) entitled “Experimental Study on High-Bonding Acrylic-polymer Waterproofing Materials”, showed that that combining acrylic ester with low-cost styrene-acrylate emulsion produces rigid waterproofing coatings with strong adhesion, excellent imperviousness, and reduced microspaces, achieving 1.8 MPa bonding strength and effective water resistance under 0.3 MPa pressure.

When to use:

- Water tanks and reservoirs for drinking water

- Swimming pools with stable structures

- Basement floors on solid foundations

- Retaining walls that do not move

- Lift pits and underground chambers

- Areas with no structural movement expected

2. Flexible Cementitious Waterproofing

Flexible cementitious waterproofing is a polymer-modified cement coating that can stretch without cracking. It contains cement, sand and special polymers that provide flexibility and elasticity. Flexible waterproofing can handle small movements in building structures over time. It works well on surfaces that experience temperature changes causing expansion and contraction.

A study from Science Direct entitled “Influences of temperature and opening rate of substrate cracks on the mechanical behaviour, crack–bridging ability and deformation mechanisms of one–component, cementitious, flexible waterproofing membranes”, showed that crack-bridging performance depends strongly on temperature and movement rate. Above the polymer’s glass transition temperature, crack-bridging ability decreases, while below it membranes behave brittle. Slower displacement rates also reduce flexibility, highlighting key factors affecting membrane durability.

When to use:

- Bathroom floors and walls

- Balconies and terraces

- Kitchen wet areas

- Areas with temperature fluctuations

- New buildings that may settle

- Surfaces with small movement expected

3. Crystalline Cementitious Waterproofing

Crystalline cementitious waterproofing is a special chemical treatment that grows crystals inside concrete permanently. It contains active chemicals that react with moisture and cement in concrete. These chemicals form millions of tiny crystals that fill all pores and microcracks. The crystals block water whilst allowing concrete to breathe naturally.

A study from Science Direct entitled “Development of cementitious capillary crystalline waterproofing agents and durability study of concrete in the presence of chloride with sulfate in aqueous environment” showed that optimised cementitious capillary crystalline waterproofing agents significantly enhance concrete durability and impermeability. Using specific proportions of EDTA, l-aspartic acid, sodium sulfate, sodium silicate, and nano-silica, substrate impermeability improved by up to 300%, strengthening resistance against water penetration and chemical attack.

When to use:

- Repairing leaking concrete structures

- Waterproofing from negative side (wet side)

- Water tanks storing drinking water

- Basement walls with active leaks

- Structures needing self-healing properties

- Concrete requiring permanent waterproofing

4. Polymer-Modified Cementitious Waterproofing

Polymer-modified cementitious waterproofing combines cement with synthetic polymers for enhanced performance and flexibility. It contains acrylic, styrene or other polymers mixed with waterproof cement. The polymers improve adhesion, flexibility and water resistance significantly compared to plain cement. Polymer-modified waterproofing bridges small cracks and withstands movement better than rigid types. It provides excellent protection in challenging conditions and demanding applications.

A study from Trans Tech Publications Ltd integrated into the Scientific.Net website entitled “The Effect of Polymer Emulsion Addition on the Setting Time, Crack Formation and Strength of Cementitious Patch Repair Mortars” found that adding polymer emulsions such as natural rubber, polyacrylonitrile, and polyvinyl acetate enhances crack resistance and improves the curing behaviour of cementitious mortars. These polymers help reduce the risk of crack formation, which is essential for preventing water penetration in concrete structures.

When to use:

- High-quality bathroom waterproofing

- Balconies and external terraces

- Swimming pools and water features

- Areas needing superior adhesion

- Surfaces with challenging conditions

- Professional waterproofing projects

5. Single-Component Cementitious Waterproofing

Single-component cementitious waterproofing is a pre-mixed powder that needs only water added before use. It contains all necessary ingredients including cement, sand, polymers and additives in one bag. Single-component systems are very easy to use requiring no complicated mixing procedures. You simply add the specified amount of clean water and mix thoroughly.

A study from Trans Tech Publications Ltd. into the Scientific.Net website entitled “The Technique of Single-Component Synchronous Grouting Allocation to Resist Floating in High Pressure Water-Rich Formation”, showed that Research indicates that in high-pressure, water-rich environments, conventional grout can be diluted, delaying strength development and reducing sealing performance. By incorporating selected organic and inorganic additives, single-component waterproofing grout achieved faster setting, improved anti-dispersion, low shrinkage, and better overall performance than two-component systems.

When to use:

- DIY waterproofing projects at home

- Small bathroom renovations

- Simple waterproofing applications

- When easy mixing is important

- Projects requiring consistent quality

- Applications by non-professional users

6. Two-Component Cementitious Waterproofing

Two-component cementitious waterproofing consists of separate powder and liquid components that you mix together. The powder contains cement, sand and special additives for waterproofing. The liquid contains polymers and chemicals that enhance performance significantly. You must mix both components together in exact proportions before use. Two-component systems provide superior adhesion, flexibility and waterproofing performance compared to single-component types.

A study from Emerald Insight entitled “Influence of cement and aggregate type on steam-cured concrete – an experimental study” found that Concretes made with HESC developed up to 83% of their design strength within just one day, demonstrating faster strength gain. Although mixtures containing recycled aggregates showed slightly lower mechanical strength, they delivered improved abrasion and skid resistance, making them suitable for pavements, flooring, and slabs.

When to use:

- Professional waterproofing installations

- High-performance applications

- Swimming pools and water tanks

- Demanding waterproofing conditions

- Projects requiring maximum durability

- Commercial and industrial waterproofing

Why is Cementitious Waterproofing Important?

Cementitious waterproofing is important because it provides affordable and reliable protection for concrete structures against water damage. Buildings need Cement waterproof coating to prevent leaks in bathrooms, basements and water tanks. It stops moisture from destroying concrete, causing mould and creating health problems. Cementitious waterproofing is safe for drinking water applications unlike many other waterproofing types. It lets concrete breathe naturally preventing pressure buildup that causes coating failure. This waterproofing method is easy to apply and repair making it practical for many projects.

Key reasons cementitious waterproofing is important:

- Protects concrete structures from water penetration and damage

- Prevents costly repairs from leaks and moisture problems

- Safe for drinking water tanks and food storage areas

- Easy to apply with basic tools and skills

- Affordable compared to other waterproofing systems

- Breathable allowing moisture vapour to escape

- Bonds permanently to concrete and masonry surfaces

- Resists mould and bacteria growth effectively

- Can be applied on damp surfaces when needed

- Provides long-lasting protection for 10-15 years

What are the Advantages of Cementitious Waterproofing?

What are the Advantages of Cementitious Waterproofing?

Advantages of cementitious waterproofing include low cost, easy application, breathability and safety for drinking water. Cement-based waterproof barrier is one of the most affordable waterproofing methods available. It uses readily available materials like cement making it cost-effective. The application process is simple requiring only basic tools and skills. Workers can apply it like plaster without special equipment or training. Cementitious sealing system bonds permanently to concrete creating very strong adhesion. It breathes naturally allowing moisture vapour to escape preventing coating damage.

Key advantages include:

- Very affordable compared to membrane systems

- Easy to apply with standard plastering tools

- Bonds extremely well to concrete and masonry

- Safe for drinking water tanks and pools

- Breathable preventing pressure buildup

- Can apply on slightly damp surfaces

- Easy to repair if damage occurs

- Long-lasting protection for 10-15 years

- Fire-resistant and non-toxic materials

- Available worldwide in many brands

Additional advantages make cementitious waterproofing perfect for many building applications worldwide. It is non-toxic and environmentally friendly using natural cement materials. Cementitious waterproofing resists fire better than polymer or bitumen systems. You can apply it in thin coats without losing ceiling height. The coating accepts paint or tiles directly without special primers. Cementitious waterproofing works well in tropical climates like Singapore’s hot humid conditions. It does not degrade from UV exposure like some polymer systems. The material is easy to source from any building supplier locally. Repairs are simple using the same material and standard tools. These advantages make cementitious waterproofing the preferred choice for residential and commercial waterproofing projects.

What are the Disadvantages of Cementitious Waterproofing?

Limitations of cementitious waterproofing include rigidity, limited flexibility and potential cracking on moving surfaces. Rigid cementitious waterproofing cannot handle structural movement or settlement at all. It cracks easily when buildings shift or when surfaces expand from temperature changes. Cementitious membrane needs proper curing with water for several days which delays projects. It does not work well on surfaces that stay constantly wet or submerged. The coating can develop hairline cracks over time reducing waterproofing effectiveness gradually.

Key limitations include:

- Rigid types crack from building movement

- Requires several days of water curing

- Not suitable for highly flexible substrates

- Less effective on negative water pressure

- Limited colour options compared to coatings

- Can be difficult to apply smoothly

- Needs skilled application for best results

- May not bridge existing cracks well

- Performance reduces in freezing conditions

- Shorter lifespan than some membrane systems

How Do You Apply Cementitious Waterproofing?

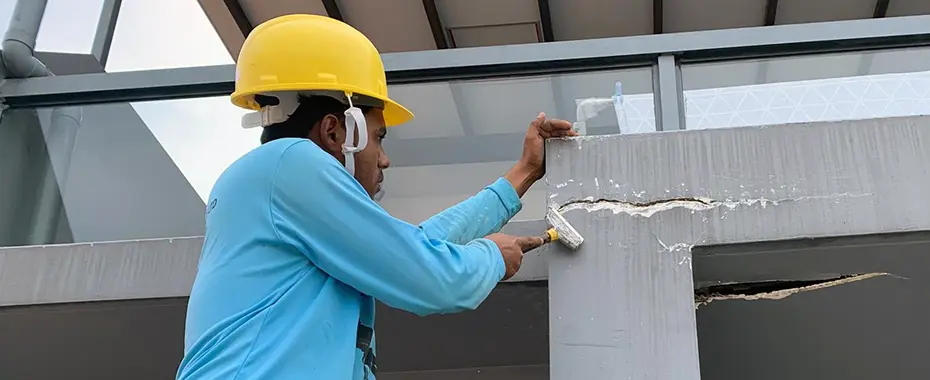

How do you apply cementitious waterproof involves careful surface preparation, proper mixing and systematic coating application. First clean the surface thoroughly removing all dirt, dust and loose materials completely. Repair cracks and holes with cement mortar before waterproofing starts. Dampen the surface with water but avoid leaving puddles anywhere. Mix cementitious waterproof powder with clean water following manufacturer instructions exactly. Apply the first coat with brush or trowel in thin even layers. Let it dry then apply second and third coats building up proper thickness. Keep the surface damp for several days after application for proper curing and strength.

Application steps include:

- Clean surface removing all contaminants completely

- Repair cracks and damage with suitable filler

- Dampen surface with water before application

- Mix powder with water to correct consistency

- Apply first coat evenly across entire surface

- Add reinforcement mesh over joints and corners

- Apply second coat after first becomes touch-dry

- Build up recommended thickness with multiple coats

- Keep surface moist during curing period

- Test waterproofing before installing finishes

Advanced waterproofing techniques like nano waterproofing use different application methods than traditional cementitious systems. However, cementitious waterproofing remains popular due to its simple reliable application process. Always follow the specific product instructions as different brands have slightly different requirements. Professional application ensures proper thickness, curing and long-lasting waterproof protection. Quality application prevents expensive failures and repairs later on. Taking time to apply Concrete waterproof coating correctly provides decades of reliable building protection.

Where is Cementitious Waterproofing Used?

Cementitious waterproofing is used in bathrooms, basements, water tanks, swimming pools and wet areas of buildings. It works perfectly for waterproofing bathroom floors and walls up to splash height. Basements use cement slurry waterproofing on internal walls and floors against dampness.

A study from E3S Web of Conferences entitled “Waterproofing material for protection of underground structures” showed that this new material exhibited strong physical and mechanical properties, making it ideal for protecting concrete structures in underground construction.

Water tanks storing drinking water rely on cementitious waterproofing for safe sealed storage. Swimming pools use this waterproofing on concrete shells before applying tiles or finishes. Kitchen wet areas around sinks benefit from Polymer-modified cementitious compound/coating protection. Balconies and terraces use flexible cementitious systems to handle weather exposure.

Common applications include:

- Bathroom floors and shower walls

- Basement walls and floors

- Water storage tanks and reservoirs

- Swimming pool shells and structures

- Kitchen wet areas and sink zones

- Balconies and external terraces

- Lift pits and underground chambers

- Retaining walls facing moisture

- Wet room floors and walls

- Foundation walls below ground

Cementitious waterproofing is also used where waterproof paint alone provides insufficient protection. Waterproof paint offers only basic moisture resistance suitable for dry areas. Wet areas like bathrooms need proper cementitious sealant systems for complete water blocking.

How Much Does Cementitious Waterproofing Cost in Singapore?

Cementitious waterproofing costs SGD $50 to $150 for materials covering small bathroom-sized areas in Singapore. A 20-kilogram bag of cementitious waterproofing powder costs SGD $40 to $80 depending on brand quality. This covers approximately 10 to 15 square metres with two coats. Premium polymer-modified cementitious waterproofing costs SGD $80 to $150 per bag. Labour charges add SGD $200 to $500 depending on area size and complexity. Complete bathroom waterproofing including materials and labour totals SGD $500 to $1,500. Flexible cementitious systems cost 20% to 40% more than rigid types.

How Long Does Cementitious Waterproofing Last?

Cementitious waterproofing lasts 10 to 15 years in typical bathroom and wet area applications. Quality polymer-modified cementitious waterproofing lasts 15 to 20 years with proper installation and maintenance. Rigid cementitious systems last 8 to 12 years on stable surfaces without movement. Flexible cementitious waterproofing lasts 12 to 18 years handling building settlement better. Crystalline cementitious systems last 30 years or more becoming permanent parts of concrete. Swimming pool cementitious waterproofing lasts 10 to 15 years with good water chemistry balance.

A study from MDPI entitled “Inventive Microstructural and Durability Investigation of Cementitious Composites Involving Crystalline Waterproofing Admixtures and Portland Limestone Cement” showed that the strength of cement-based waterproofing lies in its ability to block water. Crystalline waterproofing admixtures (CWA) enhance concrete by filling pores, reducing permeability, and forming microscopic crystals that seal tiny cracks. Studies show different CWA types create unique crystal structures and improve chemical composition, making the concrete more durable. By strengthening both microstructure and overall performance, cementitious waterproofing with CWAs offers a reliable, long-lasting solution to protect buildings from water damage.

FAQ’s About Cementitious Waterproofing

Yes, cementitious waterproofing can stop active leaks using crystalline or quick-setting formulations designed for this purpose. Crystalline cementitious waterproofing reacts with water in leaks to form crystals that seal cracks. Quick-setting cementitious plugs stop flowing water within minutes. However, standard cementitious waterproofing cannot stop active leaks and needs dry surfaces. You must use specialized products designed specifically for wet conditions and active water flow.

No, standard rigid cementitious waterproofing is not flexible and cracks easily with movement. However, Flexible cementitious waterproofing slurry/mortar containing polymers can stretch slightly without cracking. Flexible types accommodate minor building settlement and temperature changes effectively. Rigid cementitious waterproofing suits only stable surfaces that do not move. Choose flexible cementitious systems for bathrooms, balconies and areas experiencing movement or thermal expansion regularly.

Yes, you can paint over cementitious waterproofing once it has fully cured. This provides additional protection and aesthetic appeal.Yes, you can paint over cementitious waterproofing once it has fully cured and dried. The waterproofing surface accepts acrylic, emulsion and waterproof paint directly without special primers. Wait at least 7 days after application before painting for proper curing. Clean the surface lightly before painting to remove any dust or powder. Painting does not affect waterproofing performance and provides decorative finish or extra protection layer.Yes, you can paint over cementitious waterproofing once it has fully cured. This provides additional protection and aesthetic appeal.

The main difference between cementitious and liquid waterproofing membrane is that cementitious uses cement-based materials whilst liquid membranes use polymers. Cementitious waterproofing is rigid or semi-flexible whilst liquid membranes are highly flexible. Cementitious costs less but liquid membranes last longer. Cementitious breathes naturally whilst some liquid membranes do not. Liquid membranes handle movement better than rigid cementitious waterproofing systems.

Cementitious waterproofing is cement-based, while bituminous waterproofing uses bitumen to create a waterproof barrier. Bitumen is more flexible, but cementitious offers stronger adhesion to surfaces.The main difference between cementitious and bituminous waterproofing is that cementitious uses cement whilst bituminous uses tar-like materials. Cementitious works well above ground whilst bituminous excels underground. Cementitious breathes allowing vapour escape whilst bituminous creates sealed barriers. Cementitious is easier to apply whilst bituminous often needs heating. Bituminous lasts longer underground but cementitious is safer for drinking water applications.

The main difference between cementitious and polyurethane waterproofing is flexibility and application method. Cementitious is rigid or semi-flexible whilst polyurethane is highly elastic and stretches. Cementitious costs less but polyurethane provides superior performance. Cementitious applies like plaster whilst polyurethane applies as liquid coating. Polyurethane resists UV damage better than cementitious waterproofing. Cementitious is better for drinking water whilst polyurethane suits exposed roofs.