Waterproofing plaster refers to a special coating applied to walls to protect them from water damage. It creates a strong, protective barrier that stops water from seeping through, ensuring your walls remain dry. Damp-proof plaster is vital in areas like basements, bathrooms, and kitchens where moisture exposure is high. It not only protects the structure of your building but also prevents issues like mould, mildew, and structural decay. By using water-resistant plaster, you safeguard your property, extend its lifespan, and avoid costly repairs in the future.

What is Waterproofing Plaster?

Waterproofing plaster is a special cement-based coating that creates waterproof barriers on walls and surfaces. It contains waterproof cement, sand and special additives preventing water penetration. Moisture-proof coating applies like normal plaster but blocks water completely when dry. It creates both a smooth finish and waterproof protection in one application. The plaster sticks strongly to brick, concrete and masonry walls permanently. Anti-leak plaster is ideal for external walls, basements and wet areas. It provides both decorative finish and complete water protection together.

Waterproofing plaster differs from regular plaster by including waterproofing additives in the mixture. Normal plaster absorbs water causing dampness and damage over time. Sealant plaster repels water keeping walls dry and protected always. It comes ready-mixed or as powder requiring water addition before use. Different formulations include cementitious, polymer-modified, acrylic and crystalline types. Each type offers specific properties for different wall applications and conditions. Professional contractors select appropriate waterproofing plaster types for specific wall requirements.

What Are the Different Types of Waterproofing Plaster?

Waterproofing plaster types include cementitious, polymer-modified, acrylic, bituminous, crystalline and lime-based formulations.

1. Cementitious Waterproofing Plaster

Cementitious waterproofing plaster is a cement-based coating containing waterproof additives creating water-resistant walls. It mixes waterproof cement, sand and special chemicals preventing water penetration. The plaster applies like standard cement plaster but blocks water when dry. It bonds permanently to concrete, brick and masonry wall surfaces strongly. Cementitious waterproofing plaster is the most economical type available widely. It provides both smooth finish and waterproof protection simultaneously. The plaster breathes naturally preventing moisture pressure buildup behind walls.

A study from the American Society of Civil Engineers (ASCE) entitled “Experimental Characterization of an Earth Eco-Efficient Plastering Mortar”, showed that earthen plastering mortars shows they are eco-efficient, technically reliable, and suitable for both historic and modern masonry. Besides aesthetic appeal, they enhance indoor hygrometric comfort, making them a sustainable option for cementitious waterproofing plaster applications.

2. Polymer-Modified Waterproofing Plaster

Polymer-Modified waterproofing plaster combines cement with synthetic polymers creating flexible water-resistant coatings. It contains acrylic, styrene or other polymers mixed with waterproof cement. The polymers improve flexibility, adhesion and water resistance significantly compared to plain cement. Polymer-modified plaster handles wall movement better than rigid cementitious types. It creates tough durable finishes resisting cracking from building settlement. A study from Taylor & Francis Online entitled “Practical Applications of Concrete-Polymer Composites”, showed that Polymer-modified waterproofing plaster offers superior tensile and flexural strength, adhesion, abrasion and chemical resistance compared to ordinary mortar. It is applied in decorative coatings, tile adhesives, precast structures, and durable bathroom and kitchen products.

3. Acrylic Waterproofing Plaster

Acrylic waterproofing plaster contains acrylic polymers creating flexible decorative water-resistant wall coatings. It is a pre-mixed paste applying easily with trowels creating textured finishes. Acrylic plaster is more flexible than cement-based types handling wall movement. A study from Journal of Civil Engineering Research & Technology entitled “Comparative Analysis of Concrete Water-Proofing Materials”, showed that Acrylic waterproofing plaster protects concrete from water infiltration, structural damage, and corrosion. It forms durable, multi-layer barriers, resists hydrostatic pressure, and prolongs concrete lifespan, offering a cost-effective, visually appealing alternative to traditional bituminous and cementitious waterproofing systems.

4. Bituminous Waterproofing Plaster

Bituminous waterproofing plaster contains tar-based materials creating strong barriers on basement and foundation walls. It mixes bitumen with cement and sand forming tough waterproof coatings. Bituminous plaster resists water pressure and soil chemicals excellently underground. It creates thick black coatings protecting walls from groundwater and moisture. A study from Universidade Católica Portuguesa entitled “Bituminous waterproofing mortar applied on masonry walls of 19th and 20th century buildings in Porto: an analytical study in the context of urban building rehabilitation”, Research on bituminous waterproofing plaster in historic Porto buildings shows it effectively resists water. Analytical studies using micro-FTIR and Py-GS/MS confirm its composition, while tests on capillarity, saturation, and permeability demonstrate its reliable waterproofing performance.

5. Crystalline Waterproofing Plaster

Crystalline waterproofing plaster contains special chemicals that grow crystals inside concrete walls permanently. It mixes crystalline compounds with cement creating self-sealing waterproof barriers. The chemicals react with moisture and cement forming millions of tiny crystals. Crystals fill all pores and microcracks blocking water whilst allowing breathing.

A study from Trans Tech Publications Ltd. into the Scientific.Net website entitled “Polymer-Modified Cement Waterproofing Coating and Cementitious Capillary Crystalline Waterproofing Materials: Mechanism and Applications”, showed that Crystalline waterproofing plaster is a modern building material that enhances construction quality, reduces energy use, and protects the environment. Its unique waterproof mechanism and cost-effectiveness make it widely used in industrial and civil buildings, offering significant economic and social benefits.

6. Lime-Based Waterproofing Plaster

Lime-based waterproofing plaster is traditional material using lime, sand and waterproofing additives. It has been used for centuries in historic buildings worldwide. Lime plaster is highly breathable allowing moisture vapour to escape naturally. It contains natural hydraulic lime mixed with waterproofing agents and sand.

A study from Science Direct entitled “Design and behavior of traditional lime-based plasters and renders. Review and critical appraisal of strengths and weaknesses” showed that Traditional lime-based waterproofing plasters are multilayer systems with fine and coarse mortars. Their performance depends on mix design, pore structure, layer interaction, and environmental conditions, offering insights for effective restoration and durable wall protection in historical and modern applications.

Why Do You Need Waterproofing Plaster for Walls?

You need waterproofing plaster for walls to prevent water damage, dampness and structural deterioration. External walls face rain, wind and moisture constantly throughout the year. Without waterproofing plaster, water soaks through walls causing internal dampness and damage. Damp walls develop mould creating unhealthy living environments for families. Water penetration weakens wall structures reducing their strength and stability significantly. Protective plaster prevents these problems protecting buildings and occupants effectively. It provides both finished surface and complete water protection simultaneously.

Key reasons you need Water-repellent plaster:

- Prevents water penetration through walls

- Stops dampness and mould growth

- Protects wall structures from damage

- Provides finished decorative surface

- Reduces maintenance and repair costs

- Improves indoor air quality

- Combines plastering and waterproofing

- Long-lasting economical protection

- Meets building standards

Which Surfaces Can You Apply Waterproofing Plaster On?

You can apply waterproofing plaster on concrete walls, brick masonry, cement rendered surfaces and various porous materials. What is waterproofing? It’s a process that creates a protective barrier to prevent water damage and ensure the longevity of your walls. It works excellently on concrete, brick, stone and cement block walls. Waterproof skim coat suits both internal and external wall surfaces effectively. You can use it on basement walls, retaining walls and foundation walls. It applies to bathroom and kitchen walls requiring moisture protection. The plaster bonds to most masonry and cementitious surfaces permanently.

Concrete Walls

Concrete walls are ideal surfaces for waterproofing plaster application creating strong permanent bonds. Concrete is porous allowing waterproofing plaster to penetrate and stick firmly. The plaster bonds chemically and mechanically to concrete surfaces permanently. Concrete walls in basements, buildings and structures all benefit from waterproofing plaster. The material prevents water soaking through concrete causing structural damage.

Masonry or Brick Walls

Masonry or brick walls are excellent surfaces for waterproofing plaster providing porous bonding surfaces. Brick and stone masonry are naturally porous absorbing water without protection. Waterproofing plaster penetrates into brick surfaces creating strong mechanical bonds. It fills pores and irregularities in masonry creating smooth waterproof finishes. Brick walls in homes, gardens and buildings all benefit from waterproofing plaster.

Cement Rendered Surfaces

Cement rendered surfaces are suitable substrates for waterproofing plaster creating compatible bonds. Cement render is similar material to waterproofing plaster ensuring excellent adhesion. The plaster bonds chemically to cement render creating strong permanent connections. Rendered walls provide smooth uniform surfaces for waterproofing plaster application.

Retaining Walls

Retaining walls are critical surfaces needing waterproofing plaster protecting against soil moisture and pressure. These walls hold back soil and groundwater constantly facing moisture. Waterproofing plaster on retaining walls prevents water soaking through causing dampness. It protects wall structures from soil chemicals and constant moisture exposure. Retaining walls without waterproofing deteriorate rapidly from water and chemical attack.

Basements and Foundation Walls

Basements and foundation walls are essential surfaces requiring waterproofing plaster against groundwater. These walls sit below ground facing constant moisture from surrounding soil. Foundation walls support entire buildings requiring protection from water damage.

Wet Areas in Bathrooms and Kitchens

Wet areas in bathrooms and kitchens are important surfaces needing waterproofing plaster protection. These walls face daily water splashes, steam and moisture constantly. Bathroom walls around showers, baths and sinks require waterproof protection. Kitchen walls near sinks and cooking areas benefit from Waterproof render. Without protection, moisture penetrates walls causing dampness in rooms behind. Damp-proof plaster prevents water damage, mould growth and structural deterioration.

Water Tanks, Reservoir Walls, and Pool Waterproofing

Water tanks and reservoir walls are critical surfaces requiring waterproofing plaster for safe water storage. These structures hold drinking water or pool water needing complete sealing. Waterproofing plaster prevents water leaking out whilst stopping contaminants entering in.

Service Yards and Utility Area Walls

Service yards and utility area walls are practical surfaces benefiting from waterproofing plaster protection. These areas house washing machines, outdoor sinks and cleaning facilities. Service yard walls face regular water exposure from various utility activities.

When Should You Use Waterproofing Plaster?

You should use waterproofing plaster during new construction before applying paint or finishes. Use it when renovating walls to upgrade their waterproof protection. Apply waterproofing plaster immediately when you notice dampness or water stains appearing. Use it before painting or finishing walls to protect decoration investments. Waterproofing plaster is essential for bathroom and kitchen walls facing moisture. Basement and foundation walls need waterproofing plaster from construction start. Retaining walls require waterproofing plaster protecting against soil moisture constantly.

- During New Construction

During new construction is the best time to apply waterproofing plaster economically and effectively. Workers access bare wall surfaces easily before finishes cover them. New walls receiveSealant plaster before paint, tiles or decorations apply.

- Before Painting or Wall Finishing

Before painting or wall finishing you should apply waterproofing plaster protecting decoration investments. Waterproofing prevents moisture damaging new paint and finishes quickly. It stops water stains bleeding through freshly painted walls ruining appearance.

- When You Notice Damp or Leaks

When you notice damp or leaks on walls you should apply waterproofing plaster immediately. Dampness appears as patches, stains or actual water on walls. It indicates existing waterproofing has failed or never existed properly. Early treatment prevents dampness damaging wall structures and interior finishes.

- On Bathroom and Kitchen Walls

On bathroom and kitchen walls you should use waterproofing plaster before tiling or finishing. These wet areas face daily water, steam and moisture exposure constantly. Bathroom walls around showers, baths and sinks need waterproof protection. Kitchen walls near sinks and cooking areas benefit from Anti-leak plaster.

- For Basements and Foundation Walls

For basements and foundation walls you should use waterproofing plaster as standard essential practice. These walls sit below ground facing constant groundwater and soil moisture. Foundation walls support entire buildings requiring maximum protection from water.

- On Retaining Walls

On retaining walls you should use waterproofing plaster as essential protection against soil moisture. These walls hold back soil and groundwater constantly facing pressure. Retaining walls without waterproofing deteriorate rapidly from moisture and chemicals. Moisture-proof coating prevents water soaking through causing structural weakening and failure.

- Before Renovation or Repairs

Before renovation or repairs you should use waterproofing plaster upgrading wall protection. Renovation provides perfect opportunity to address hidden moisture problems properly. Workers access walls easily whilst removing old finishes and damaged materials. Water-resistant plaster prevents future dampness problems after expensive renovation work.

- In High-Humidity Environments

In high-humidity environments you should use waterproofing plaster preventing constant moisture damage. Singapore’s tropical climate maintains high humidity year-round testing walls constantly. Coastal areas face humidity and salt spray damaging walls rapidly. High-humidity environments promote condensation on walls leading to dampness.

What Materials Are Used in Waterproofing Plaster?

Materials used in waterproofing plaster include waterproof cement, fine sand, polymer additives and special waterproofing chemicals. Waterproof cement is the main binding material providing strength and adhesion. Fine sand provides bulk and texture to the plaster mix. Polymer additives improve flexibility, adhesion and water resistance significantly. Waterproofing chemicals create barriers blocking water penetration through plaster. Some formulations include crystalline compounds growing crystals in concrete permanently. Acrylic or styrene polymers enhance flexibility accommodating wall movement. Lime-based plasters use hydraulic lime instead of cement traditionally.

Main waterproofing plaster materials:

- Waterproof cement (ordinary or white)

- Fine sand (washed and graded)

- Polymer additives (acrylic, styrene)

- Waterproofing chemicals

- Crystalline compounds

- Lime (for heritage work)

- Bonding agents

- Plasticizers

- Retarders (slow curing)

- Water (clean and potable)

How Do You Apply Waterproofing Plaster?

You apply waterproofing plaster by following systematic steps ensuring proper surface preparation, mixing and application techniques.

Step 1: Inspect and Prepare the Wall Surface

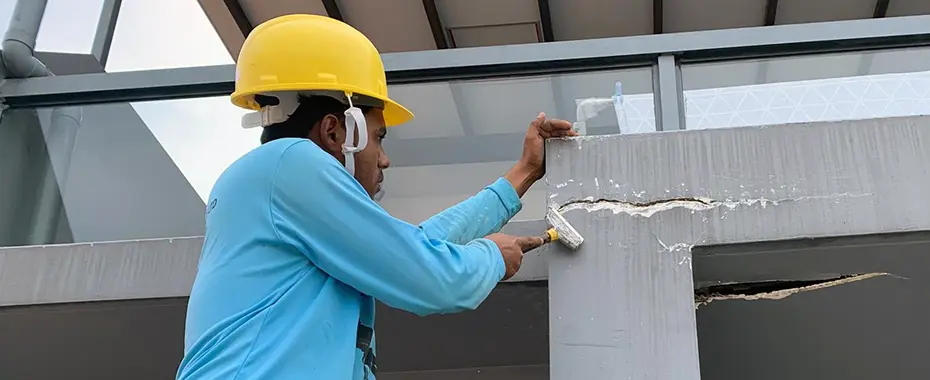

Examine the entire wall surface thoroughly identifying cracks, holes and any damage needing repair before starting. Clean the wall completely removing all dirt, dust, loose material, paint and contaminants affecting plaster adhesion.

Step 2: Repair Damaged Areas

Fill all cracks and holes with suitable cement mortar or filler ensuring surfaces are sound and stable. Let repairs cure properly for at least 24 hours before applying waterproofing plaster over them.

Step 3: Dampen the Wall Surface

Spray or brush clean water onto the wall surface dampening it thoroughly but avoiding puddles forming. Damp surfaces help waterproofing plaster bond better whilst preventing too-rapid moisture loss during curing.

Step 4: Apply Bonding Agent or Primer

Brush bonding agent or primer onto dampened wall surfaces following manufacturer instructions for better plaster adhesion. Let primer become tacky before applying waterproofing plaster for maximum bonding strength achieved.

Step 5: Mix Waterproofing Plaster Properly

Mix waterproofing plaster powder with clean water in correct proportions specified by the manufacturer’s instructions. Stir thoroughly until achieving smooth lump-free consistency suitable for application without being too thick or thin.

Step 6: Apply First Coat of Plaster

Apply first coat of waterproofing plaster to wall using steel trowel in even strokes covering entire surface. Build up thickness of 6 to 10 millimetres ensuring complete coverage without thin spots anywhere.

Step 7: Scratch the First Coat

Scratch the first plaster coat surface with scratching tool whilst still wet creating grooves for second coat. The rough scratched surface helps second coat bond strongly to first coat preventing delamination later.

Step 8: Let First Coat Set

Allow first plaster coat to set for 12 to 24 hours depending on weather and temperature conditions. The coat should be firm but not completely dry before applying second coat over it.

Step 9: Dampen First Coat

Spray clean water on first coat surface dampening it before applying second plaster coat. This prevents first coat absorbing water from second coat too quickly causing bonding problems.

Step 10: Apply Second Coat

Apply second waterproofing plaster coat building up total thickness to 12 to 20 millimetres recommended. Trowel smooth creating even finished surface ready for painting or decorative treatment when cured.

Step 11: Cure the Plaster Properly

Keep waterproofing plaster damp for at least 7 days by spraying water regularly twice daily. Proper curing allows plaster to develop maximum strength and waterproof properties achieving best performance.

Step 12: Protect and Finish

Protect cured waterproofing plaster from damage until painting or finishing as designed for project. Apply paint, tiles or decorative finishes only after plaster has cured completely for specified time.

How Does Waterproofing Plaster Support Pool Waterproofing?

Waterproofing plaster supports pool waterproofing by creating smooth watertight surfaces inside swimming pool structures. Traditional pool waterproofing uses specialized waterproof plaster finishes applied to concrete pool shells. The plaster seals concrete preventing water leaking out whilst creating attractive smooth finishes. Pool plaster contains white cement, marble dust and waterproofing additives resisting chlorine. It provides durable surfaces lasting 10 to 15 years with proper maintenance. Modern pool waterproofing combines waterproof plaster with additional membrane systems for complete protection. Professional pool contractors apply waterproofing protective plaster ensuring watertight smooth pool surfaces.

Who Should Handle Waterproofing Plaster Work?

Professional waterproofing plaster service providers can handle waterproofing plaster work ensuring quality long-lasting results.

- Assessment and Inspection: Professional contractors visit your property conducting thorough inspections of all walls needing waterproofing plaster treatment. They identify problem areas, assess wall conditions and determine appropriate waterproofing plaster types for specific requirements.

- Detailed Quotation Preparation: Contractors prepare written quotations detailing scope of work, materials to be used, costs and project timeline. They explain different waterproofing plaster options helping you choose appropriate systems for your walls and budget.

- Surface Preparation Work: Professional teams prepare wall surfaces properly removing all contaminants, repairing damage and ensuring sound substrates. They understand critical importance of thorough preparation for successful waterproofing plaster adhesion and long-term performance.

- Material Selection and Procurement: Contractors select quality waterproofing plaster materials from reputable manufacturers ensuring reliable performance and longevity. They procure correct quantities avoiding wastage whilst ensuring adequate materials for complete coverage throughout.

- Professional Application Techniques: Experienced plasterers apply waterproofing plaster using proper techniques ensuring even thickness and complete coverage everywhere. They build up multiple coats systematically achieving specified total thickness for adequate waterproof protection.

- Quality Control and Testing: Professional contractors inspect completed waterproofing plaster checking for defects, thin spots or inadequate coverage problems. They perform water testing when appropriate confirming waterproofing works correctly before finishing or decoration.

- Proper Curing Management: Contractors ensure waterproofing plaster cures properly by maintaining moisture for specified periods achieving maximum strength. They protect fresh plaster from damage, rain and premature drying during critical curing phase.

- Warranty and Documentation: Professional service providers offer warranties on waterproofing plaster work protecting your investment from failures. They provide documentation including material specifications, application details and maintenance instructions for future reference.

How Do You Choose a Professional Waterproofing Plaster Service Provider?

You choose a professional waterproofing plaster service provider by researching companies, checking credentials and comparing qualifications.

Step 1: Research and Shortlist Companies

Search online for licensed waterproofing contractors in Singapore reading reviews and checking company websites carefully. Shortlist at least three companies with good reputations, proper licenses and relevant waterproofing plaster experience.

Step 2: Verify Licenses and Certifications

Check that contractors hold valid Building and Construction Authority (BCA) licenses required for waterproofing work. Verify professional certifications, association memberships and worker training ensuring qualified experienced teams handle your project.

Step 3: Request Detailed Quotations

Contact shortlisted companies requesting written quotations detailing scope, materials, timeline and costs for your project. Compare quotations carefully checking what preparation work, materials and warranties are included in pricing offered.

Step 4: Check References and Past Work

Ask contractors for references from past clients with similar waterproofing plaster projects completed successfully. Contact references asking about work quality, professionalism, timeline adherence and overall satisfaction with contractor performance.

Step 5: Interview and Assess Contractors

Schedule consultations with contractors assessing their knowledge, communication and professionalism during meetings and site visits. Ask specific questions about waterproofing plaster types, application methods and how they handle potential problems.

Step 6: Review Insurance Coverage

Verify contractors carry adequate public liability insurance and workmen compensation coverage protecting you from liability. Request proof of insurance ensuring coverage is current and adequate for your project size.

Step 7: Evaluate Communication and Responsiveness

Assess how quickly and clearly contractors respond to inquiries and concerns throughout quotation process. Good communication indicates professionalism and reliability for successful project completion and future support needs.

Step 8: Compare Value Not Just Price

Consider overall value including materials quality, warranty coverage, reputation and experience rather than choosing cheapest quote. Lowest price often means compromised quality, cheaper materials or inadequate coverage causing expensive failures later.

Step 9: Review Contract Terms Carefully

Read written contracts thoroughly before signing ensuring scope, timeline, payment schedule and warranties are clearly defined. Clarify any unclear terms or conditions preventing misunderstandings and disputes during project execution.

Step 10: Trust Your Instincts

Trust your gut feeling about contractor professionalism, honesty and reliability based on all interactions throughout process. Choose contractors you feel comfortable with and confident will deliver quality waterproofing plaster work.

How Much Does Waterproofing Plaster Cost in Singapore?

Waterproofing plaster cost in Singapore ranges from SGD $15 to $40 per square metre depending on plaster type and wall condition. Cementitious waterproofing plaster costs SGD $15 to $25 per square metre for basic applications. Polymer-modified waterproofing plaster costs SGD $20 to $30 per square metre providing enhanced performance. Acrylic waterproofing plaster costs SGD $25 to $40 per square metre for decorative finishes. Labour charges represent 60% to 70% of total waterproofing plaster costs. Professional contractors charge SGD $80 to $150 per hour for experienced plasterers. Minimum job charges typically start from SGD $300 to $500 for small projects.

Material costs for waterproofing plaster vary based on type, brand and quality selected. Basic cementitious waterproofing plaster costs SGD $5 to $10 per 25-kilogram bag covering 10 to 12 square metres. Polymer-modified plaster costs SGD $15 to $25 per bag providing better performance. Acrylic waterproofing plaster costs SGD $30 to $50 per 20-litre pail covering 15 to 20 square metres. Additional costs include surface preparation, crack repairs and old plaster removal if renovating. Removing old plaster costs SGD $10 to $20 per square metre extra. Extensive repairs add SGD $100 to $500 depending on damage extent. Although quality waterproofing plaster costs more initially, it prevents expensive water damage repairs later. Professional application ensures proper coverage and thickness providing long-lasting reliable waterproof protection for buildings.

How Long Can You Keep a Waterproof Plaster On?

You can keep waterproof plaster on walls indefinitely as it provides permanent waterproof protection lasting decades. Once applied and cured, waterproofing plaster becomes integral part of wall structure permanently. It does not need removal or replacement unless damaged or walls require major renovation. The plaster continues protecting walls for 10 to 20 years or longer with proper maintenance. You only remove waterproofing plaster when renovating completely or changing wall finishes. Quality waterproofing plaster properly applied lasts the building’s lifetime potentially with minimal maintenance.

How Long Does Waterproofing Plaster Last?

Waterproofing plaster lasts 10 to 25 years in Singapore depending on type, application quality and environmental exposure. Cementitious waterproofing plaster lasts 10 to 15 years on external walls facing weather. Polymer-modified plaster lasts 15 to 20 years providing enhanced durability and flexibility. Acrylic waterproofing plaster lasts 12 to 18 years with good UV resistance. Lime-based plaster lasts 15 to 25 years in heritage building applications. Professional application maximizes waterproofing plaster lifespan significantly compared to amateur work. Proper curing and maintenance extend plaster life by 20% to 40% beyond typical expectations.

What are the Common Mistakes When Using Waterproofing Plaster?

Common mistakes when using waterproofing plaster include poor surface preparation, incorrect mixing, inadequate thickness and improper curing.

Mistake 1: Poor Surface Preparation

Applying waterproofing plaster on dirty, oily or loose surfaces prevents proper adhesion causing plaster failure quickly. Always clean surfaces thoroughly removing all contaminants, loose material and paint before applying waterproofing plaster.

Mistake 2: Inadequate Surface Dampening

Applying plaster on completely dry surfaces causes rapid water loss preventing proper curing and bonding. Always dampen wall surfaces adequately before applying waterproofing plaster ensuring good adhesion and curing.

Mistake 3: Incorrect Mixing Proportions

Mixing waterproofing plaster with wrong water proportions creates weak plaster that cracks and fails prematurely. Always follow manufacturer’s mixing instructions precisely using correct water-to-powder ratios for proper performance.

Mistake 4: Applying Too Thin

Applying waterproofing plaster too thin provides inadequate coverage allowing water penetration through weak spots. Always build up recommended thickness of 12 to 20 millimetres ensuring complete waterproof protection.

Mistake 5: Rushing Between Coats

Applying second coat before first coat sets properly causes delamination and bonding failures between layers. Always wait recommended time between coats allowing proper setting for strong permanent bonding.

Mistake 6: Poor Curing Practices

Not keeping waterproofing plaster damp during curing prevents it developing full strength and waterproof properties. Always cure plaster properly by keeping it moist for at least 7 days for maximum performance.

Mistake 7: Applying in Wrong Weather

Applying waterproofing plaster in extreme heat, cold or rain causes curing problems and plaster failure. Always apply plaster in suitable weather conditions following manufacturer’s temperature and humidity recommendations carefully.

Mistake 8: Ignoring Crack Repairs

Applying waterproofing plaster over existing cracks without proper repair allows cracks to propagate through new plaster. Always repair cracks properly before applying waterproofing plaster ensuring sound stable substrates underneath.

Mistake 9: Using Wrong Plaster Type

Selecting inappropriate waterproofing plaster type for specific wall conditions and exposure causes premature failure. Always choose plaster formulations suited to wall material, location and water exposure levels.

Mistake 10: Skipping Primer Application

Not applying bonding agent or primer on smooth surfaces prevents waterproofing plaster adhering properly. Always use primers when recommended by manufacturers ensuring strong permanent plaster adhesion.

Mistake 11: Poor Workmanship

Applying waterproofing plaster unevenly or carelessly creates thin spots and weak areas allowing water penetration. Always apply plaster carefully and evenly ensuring consistent thickness and complete coverage throughout.

Mistake 12: Painting Too Soon

Painting waterproofing plaster before it cures completely traps moisture causing paint peeling and plaster damage. Always wait at least 14 to 28 days after plastering before painting allowing complete curing.

FAQ’s

Waterproofing comes first before plastering in wet areas like bathrooms and basements. You apply waterproofing membranes or coatings to bare walls first creating barriers. Then you apply plaster or tiles over the cured waterproofing. However, waterproofing plaster combines both steps applying waterproof plaster directly to walls. This provides plastering and waterproofing together in single application economically and efficiently.

Cementitious waterproofing is best for plastering as both are cement-based creating compatible bonding. Polymer-modified waterproofing also works excellently under plaster providing flexibility and strength. These waterproofing types accept plaster directly without special preparation needed. Liquid membranes and coatings may need primers before plastering over them. Choose waterproofing types specifically designed to accept plaster finishes for best results and longevity.

Yes, waterproofing plaster can stop water seepage when applied correctly with proper thickness and coverage. It creates barriers preventing water penetrating through walls causing dampness and damage. Waterproofing plaster fills pores and creates dense coatings blocking water effectively. However, you must repair major cracks first before applying plaster. Professional application ensures adequate thickness and coverage stopping seepage completely and permanently.

Plastering over damp walls causes serious problems including poor adhesion, efflorescence and plaster failure quickly. The plaster does not bond properly to damp surfaces falling off within months. Trapped moisture causes salts migrating to surface creating white deposits and staining. Dampness prevents plaster curing properly reducing strength significantly. Always dry walls completely before plastering ensuring successful long-lasting results.

Yes, you can apply waterproofing plaster over old walls if surfaces are sound, clean and properly prepared. Remove loose paint, damaged plaster and all contaminants before applying waterproofing plaster. Repair cracks and ensure walls are stable without major structural problems. Apply bonding agent or primer improving adhesion to old surfaces. Professional assessment ensures old walls are suitable for waterproofing plaster application.

Yes, waterproofing plaster can prevent mould and dampness by blocking water penetration through walls completely. It stops moisture entering walls eliminating conditions mould needs to grow. Waterproofing plaster keeps walls dry preventing damp patches and musty odours. It creates healthy indoor environments by controlling moisture effectively. However, you must address existing dampness sources before applying plaster ensuring complete protection.