PU Injection Waterproofing is a highly effective method used to prevent water from entering a structure. PU injection waterproofing is essential for repairing leaking basements, tunnels and concrete structures quickly. It stops active water leaks immediately even whilst water is flowing through. The PU resin injection technique works from inside buildings without needing external wall access. Workers can repair leaks in occupied buildings with minimal disruption. PU injection avoids expensive excavation and concrete demolition saving time and money. It is the preferred method for emergency leak repairs worldwide. Professional contractors use Polyurethane foam injection waterproofing to solve challenging waterproofing problems effectively.

What Is PU Injection Waterproofing?

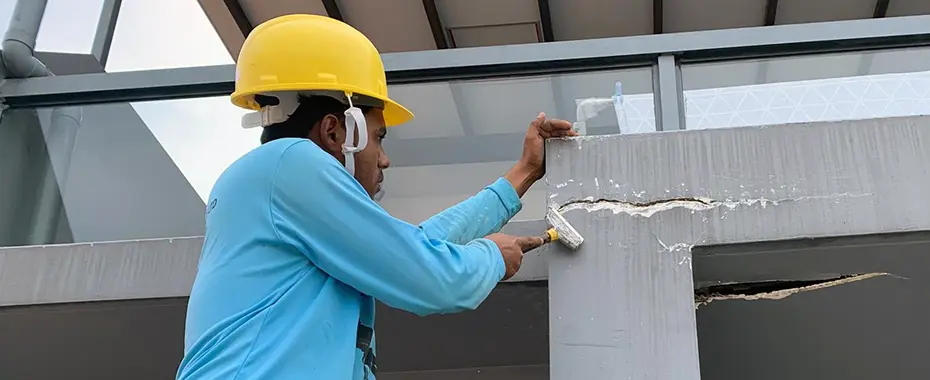

PU injection waterproofing is a specialized technique that pumps polyurethane material into cracks to stop water leaks. It involves drilling holes along cracks and injecting liquid polyurethane under pressure. The polyurethane reacts with water in cracks expanding many times its original size. It fills all voids, gaps and cracks completely creating permanent watertight seals.

A study from Science Direct entitled “Evaluation of polyurethane resin injection for concrete leak repair”, showed that polyurethane resin injection for stopping water leakage in concrete structures. The resin expands upon contact with water, creating a durable, elastic foam that effectively blocks cracks and voids. It significantly reduces concrete permeability and provides a reliable solution for waterproofing various concrete elements.

What Are the Different Types of PU Injection for Waterproofing?

PU injection for waterproofing types include hydrophilic, hydrophobic, flexible, rigid, high-pressure, low-pressure and cementitious grout formulations. Different Pressure injection waterproofing (PU-based) types work through various chemical reactions and expansion characteristics. Hydrophilic polyurethanes need moisture to cure and expand forming gels or foams. Hydrophobic polyurethanes cure without water creating flexible rubber-like seals. Single-component systems react with air moisture whilst two-component systems mix before injection. Fast-reacting formulations stop flowing water within seconds. Slow-reacting types penetrate deeper into structures before expanding.

1. Hydrophilic PU Injection

Hydrophilic PU injection uses water-reactive polyurethane that expands when contacting moisture in cracks. It is specifically designed for stopping active water leaks in wet conditions. Hydrophilic means “water-loving” so this polyurethane actively seeks and reacts with water. When injected into wet cracks, it expands forming gel or foam filling all voids. The expanding material pushes water out whilst creating permanent waterproof seals. Hydrophilic PU continues expanding after injection ensuring complete crack filling. It is the most common type for emergency leak repairs.

A study conducted by Science Direct titled “Hydrophilic thermoplastic polyurethanes for the manufacturing of highly dosed oral sustained release matrices via hot melt extrusion and injection molding”, showed that hydrophilic thermoplastic polyurethane matrices with high water uptake capacity and controlled performance characteristics. Their hydrophilic structure and adjustable properties demonstrate strong penetration, expansion, and stability potential, supporting the technical foundation of hydrophilic PU injection systems for effective moisture control applications.

2. Hydrophobic PU Injection

Hydrophobic PU injection uses water-repelling polyurethane that cures without needing moisture in cracks. It is designed for dry cracks where future water exposure is expected. Hydrophobic means “water-hating” so this polyurethane repels water creating sealed barriers. When injected into dry cracks, it expands moderately forming flexible rubber-like seals. The material bonds strongly to dry concrete surfaces creating permanent waterproof barriers. Hydrophobic PU does not need water to cure making it suitable for prevention. It creates strong elastic seals resisting future water pressure effectively.

A study from Wiley Online Library entitled “Preparation of thermoplastic polyurethane blend foams with controlled hydrophobicity via vapor induced phase separation”, showed that PDMS-modified thermoplastic polyurethane significantly enhances hydrophobic performance, increasing water contact angle and improving oil adsorption efficiency. This advanced material design supports effective oil–water separation, highlighting the potential of hydrophobic PU injection technology for superior moisture resistance, sealing performance, and durability.

3. Flexible PU Injection

Flexible PU injection uses elastic polyurethane formulations that remain permanently flexible after curing. It is designed for cracks in structures experiencing movement or vibration. Flexible PU accommodates expansion, contraction and settlement without breaking seals. The material cures into rubber-like consistency stretching with structural movement. It prevents cracks from reopening as buildings shift over time. Flexible PU is essential for living structures like bridges and high-rise buildings. The flexibility ensures long-lasting waterproof seals despite ongoing movement.

A study from the American Society of Civil Engineers (ASCE) entitled showed that foamable polymers used in underground grouting shows strong water-plugging performance. NMR analysis confirmed sealing pressure thresholds up to 1.50 MPa, increasing with density. Findings support the effectiveness of flexible PU injection for waterproofing cracks and preventing water intrusion in underground structures.

4. Rigid PU Injection

Rigid PU injection uses hard polyurethane formulations that cure into strong solid material. It is designed for providing structural support along with waterproofing benefits. Rigid PU expands less than flexible types creating dense hard foam. The material bonds concrete pieces together strengthening weakened structures. It fills voids completely providing load-bearing capacity after curing. Rigid PU is ideal for stable cracks not experiencing movement. The hardness prevents water penetration whilst adding structural integrity.

A study from Taylor & Francis Online entitled “Consolidation and waterproofing by injection of PU resins. Ilarion Dam – treatment on the spillway tunnel”, showed that Ground conditions in underground construction are often unpredictable, leading to fractures and water ingress. The study highlights how fast-reacting, low-viscosity PU resins effectively stabilized and sealed tunnel strata. Results from the Ilarion Dam project demonstrate the practical benefits of rigid PU injection in controlling water flow and ground instability.

5. High-Pressure PU Injection

High-pressure PU injection forces polyurethane deep into fine cracks using powerful pumping equipment. It is designed for sealing hairline cracks and tight spaces requiring penetration. High-pressure injection uses specialized pumps generating significant force pushing material into cracks. The pressure forces PU through tortuous crack paths reaching deep into structures. It fills microcracks completely that low-pressure methods cannot reach. High-pressure injection requires professional equipment and trained operators. The technique achieves complete crack penetration ensuring thorough waterproofing.

A study from MDPI entitled “Experimental Study on Improving the Impermeability of Concrete under High-Pressure Water Environments Using a Polymer Coating”, showed that high-pressure tunnel waterproofing shows that advanced polymer coatings significantly improve concrete impermeability. Tests confirm resistance up to 3 MPa pressure and major reductions in seepage. Findings support the effectiveness of High-Pressure PU Injection and protective coatings in demanding water-pressure environments.

6. Low-Pressure PU Injection

Low-pressure PU injection uses gentle pumping forcing polyurethane into wider cracks and voids safely. It is designed for sealing larger cracks without risking concrete damage from pressure. Low-pressure injection uses hand pumps or low-powered equipment generating controlled force. The gentle pressure fills wide cracks completely without creating additional damage. It suits old or weak concrete that might crack from high-pressure injection. Low-pressure methods are safer for DIY applications and small repairs. The technique achieves effective sealing in appropriate crack sizes economically.

A study from MDPI entitled “Technical Evaluation Method for Physical Property Changes due to Environmental Degradation of Grout-Injection Repair Materials for Water-Leakage Cracks”, showed that evaluates grout-injection materials for concrete crack repair under ISO TS 16774 standards. It highlights that low-pressure PU injection is essential for direct crack sealing, preventing additional damage while effectively controlling water leakage in underground concrete structures.

7. PU Injection With Cementitious Grout

PU injection with cementitious grout combines polyurethane injection with cement grouting for comprehensive repairs. It uses PU to stop active leaks first then follows with cement grout for permanent strength. The PU creates immediate waterproof seals whilst cement provides long-term structural stability. This combination repairs large structural cracks requiring both sealing and strengthening. Workers inject PU stopping water flow then pump cement grout filling remaining voids. The hybrid approach provides superior results compared to either method alone.

A study from MDPI entitled “Properties and Microstructure of a Cement-Based Capillary Crystalline Waterproofing Grouting Material” cement-based capillary crystalline waterproofing (CCCW) grout shows improved sealing and strength compared to traditional cement grout. By promoting cement hydration and filling micro-voids, CCCW enhances waterproofing performance, reduces permeability, and provides stronger, longer-lasting protection against water leakage in structures.

How Does PU Injection Waterproofing Work?

PU injection waterproofing works by pumping liquid polyurethane into cracks where it reacts and expands to create waterproof seals. Workers drill small holes along cracks at regular intervals spacing them 15 to 30 centimetres apart. They insert special injection ports called packers into these drilled holes. The injection machine pumps liquid polyurethane through packers into the crack under controlled pressure.

The polyurethane flows through the crack filling all spaces and voids completely. When it contacts water or moisture, the polyurethane expands rapidly becoming foam or gel. The expanding material pushes water out whilst filling the crack creating permanent waterproof barriers.

What Are the Benefits of PU Injection Waterproofing?

The benefits of PU injection waterproofing include stopping active leaks immediately without excavation or concrete removal. This waterproofing method works whilst water is actively flowing through cracks. It avoids expensive excavation and demolition saving time and money significantly. Chemical grouting (polyurethane) works from inside buildings without needing external wall access. The technique causes minimal disruption to building occupants during repairs. Workers complete repairs in hours not days allowing quick return to normal. The expanding foam fills all voids ensuring complete crack sealing. PU injection is perfect for emergency leak repairs in basements and tunnels.

Key benefits include:

- Stops active leaks immediately

- No excavation or demolition needed

- Works from inside buildings

- Minimal disruption to occupants

- Quick application and results

- Cost-effective repair method

- Complete crack filling

- Suitable for emergency repairs

- Works in wet conditions

- Permanent waterproof seals

What Materials Are Used in PU Injection Waterproofing?

Materials used in PU injection waterproofing include various polyurethane formulations, injection equipment and installation accessories. The main material is liquid polyurethane resin available in different chemical formulations. Hydrophilic polyurethanes react with water forming expanding gels or foams. Hydrophobic polyurethanes cure without moisture creating flexible rubber seals. Single-component PU systems come ready to use from containers. Two-component systems require mixing resin and catalyst before injection. Each formulation type suits specific crack conditions and waterproofing requirements. Quality polyurethanes from reputable manufacturers ensure reliable long-lasting results.

Main materials include:

- Hydrophilic polyurethane resin

- Hydrophobic polyurethane resin

- Single-component PU systems

- Two-component PU systems

- Fast-reacting formulations

- Slow-reacting formulations

- Flexible PU types

- Rigid PU types

- Primer chemicals

- Cleaning solvents

When Should You Use PU Injection Waterproofing?

You should use PU injection waterproofing when facing active leaks in basements, tunnels or concrete structures. This method stops flowing water immediately whilst the leak is happening. Use PU injection for emergency repairs preventing flooding in occupied buildings. It works perfectly for repairing leaks that traditional waterproofing cannot reach easily. PU resin injection suits situations where excavation is impossible or too expensive. The technique is ideal when you need quick results without major building disruption. Unlike waterproof coatings that need dry surfaces, Injection grouting with polyurethane works in wet conditions. It provides protection that is truly waterproof and water resistant, creating a complete barrier against water penetration.

Use PU injection when:

- Cracks are actively leaking

- Active water leaks are occurring

- Emergency repairs are needed

- Working from inside only

- Need permanent waterproof seal

- Want cost-effective repairs

How Do You Use PU Injection Waterproofing?

You use PU injection waterproofing by first inspecting cracks to determine their extent and water flow. Examine the entire crack length marking start and end points clearly. Check if water is actively flowing or if cracks are dry. Measure crack width and depth estimating the volume needing filling. Identify the crack type whether structural, settlement or thermal movement. Determine appropriate polyurethane formulation based on crack conditions observed. Plan injection port spacing typically every 15 to 30 centimetres. Prepare all equipment, materials and safety gear before starting work.

To use Polyurethane injection waterproofing, the following steps are followed:

1. Identify Leaks: First, the areas where water is entering are identified.

2. Drill Holes: Small holes are drilled into the concrete or wall, aligned with the cracks.

3. Inject Resin: The polyurethane resin is injected into the holes, filling the cracks.

4. Allow to Cure: The resin expands, fills gaps, and hardens, creating a waterproof seal.

How Much Does PU Injection Waterproofing Cost in Singapore?

PU injection waterproofing cost in Singapore ranges from SGD $50 to $200 per metre depending on crack size and complexity. Simple basement crack repairs cost SGD $50 to $100 per metre for straightforward applications. Complex structural cracks requiring high-pressure injection cost SGD $100 to $200 per metre. Wide cracks needing more material cost more than hairline cracks. Minimum charges typically start from SGD $300 to $500 for small residential jobs. Large commercial projects benefit from economies of scale reducing per-metre costs. Emergency or after-hours services cost 30% to 50% more than standard rates.

Material costs represent 30% to 50% of total polyurethane injection waterproofing expenses in Singapore. Quality polyurethane costs SGD $50 to $150 per litre depending on formulation. Hydrophilic PU is generally cheaper than hydrophobic or hybrid types. Injection packers cost SGD $2 to $5 each with dozens needed per project. Labour charges account for 50% to 70% of total costs reflecting skilled work. Professional contractors charge SGD $80 to $150 per hour for experienced technicians. Complete basement wall treatment costs SGD $1,500 to $5,000 depending on leak extent. Swimming pool crack repairs cost SGD $1,000 to $3,000 for complete sealing. Although PU grouting waterproofing seems expensive, it costs 50% to 70% less than traditional excavation and waterproofing methods.

How Long Does PU Injection Waterproofing Last?

PU injection waterproofing lasts 10 to 15 years in typical basement and concrete structure applications. Quality polyurethane formulations from reputable manufacturers provide reliable long-term performance. Hydrophobic PU generally lasts longer than hydrophilic types in underground conditions. Flexible PU formulations last longer in structures experiencing ongoing movement. Rigid PU provides permanent sealing in stable cracks without movement. Professional application maximizes lifespan ensuring proper material selection and injection technique. Harsh chemical environments reduce lifespan requiring more frequent re-treatment.

Singapore’s tropical climate affects PU grouting waterproofing lifespan through heat and humidity exposure. High temperatures accelerate chemical aging of polyurethane materials gradually. Constant high humidity keeps polyurethane damp potentially reducing performance over time. Underground applications remain cooler protecting PU from extreme temperatures. Properly applied Polyurethane grouting often exceeds expected 10-15 year lifespan significantly. Regular inspections help identify any degradation needing attention early. Small top-up injections extend waterproofing life cost-effectively. Well-maintained PU injection waterproofing can last 15 to 20 years. Quality professional application ensures maximum durability and value.

Should You Hire a Specialist for PU Injection Waterproofing?

You should hire a specialist for PU injection waterproofing to ensure effective long-lasting leak repairs. Specialists have training, experience and equipment for successful PU chemical injection applications. They understand which polyurethane formulations suit different crack types and conditions. Professional specialists avoid common mistakes that cause DIY repairs to fail quickly. They provide warranties on work protecting your investment from failures. Specialists complete repairs faster with better results than amateur attempts. Although hiring professionals costs more initially, it prevents expensive re-treatment later. Waterproof flooring and other critical applications always need specialist expertise.

Reasons to hire specialists:

- Professional training and expertise

- Proper injection equipment

- Correct material selection

- Warranty protection included

- Faster completion times

- Better long-term results

- Safety compliance

- Troubleshooting skills

- Quality assurance

- Cost-effective long-term

FAQ’s

Yes, PU injection waterproofing is suitable for concrete cracks and is specifically designed for this purpose. It works excellently on hairline cracks, wide cracks and structural cracks in concrete. The expanding polyurethane fills all voids completely creating permanent waterproof seals. Polyurethane crack injection handles both dry and actively leaking concrete cracks effectively. It is the preferred method worldwide for repairing concrete crack leaks.

Yes, PU injection waterproofing is a permanent solution lasting 10 to 15 years or longer. The cured polyurethane bonds permanently to concrete creating strong durable seals. Quality professional application ensures long-lasting waterproof protection without failure. However, severe ongoing structural movement may require eventual re-treatment. Regular inspections and small top-up injections extend the permanent protection indefinitely. It provides the most permanent solution for concrete crack waterproofing.

No, PU injection waterproofing does not require hacking or demolition of concrete structures. It works through small drilled holes without breaking or removing concrete. The technique repairs leaks from inside buildings without external excavation. This saves 50% to 70% costs compared to traditional demolition and rebuilding. Only small holes need patching after injection making it minimally invasive. It is the perfect solution avoiding expensive demolition work.

Yes, PU injection waterproofing can repair basement leaks quickly and effectively from inside. It stops active water flow through basement wall cracks immediately. The technique works without needing external excavation around foundations. PU resin injection handles groundwater pressure repairing even severe basement flooding. It is the most cost-effective method for basement leak repairs. Professional contractors use PU injection for 90% of basement waterproofing repairs.

The key differences are PU expands whilst epoxy does not, and PU stops water whilst epoxy provides structural strength. Polyurethane injection waterproofs by expanding to fill voids and seal against water. Epoxy injection strengthens concrete by bonding cracks together without expansion. PU works on wet actively leaking cracks whilst epoxy needs dry conditions. Use PU for waterproofing and epoxy for structural repairs requiring strength.